Community-based multiplication of sweet potato vines and cuttings

Summary

The availability, access and quality of life sweet potato planting material in rural communities can be enhanced by organizing community-based multiplication of vines and cuttings at medium to large scale. Strong linkages between multipliers and sellers formed under this strategy are further giving rise to more reliable and cost-effective supply of vines and cuttings to farmers. Improving the multiplication of planting material through multi-stakeholder collaboration can offer major gains in the yield and resilience of sweet potato crops, if strategies are properly aligned with agro-ecological and socio-economic factors.

About the Solution

The advantages of community-based multiplication strategies for sweet potato are that they allow to make substantial improvements in the quality control of planting materials and also lower its retail prices, particularly in smallholder farmer landscapes with limited infrastructures and access to markets. Multiplication of vines and cuttings at medium to large scale through joint investments enables specialists to be engaged, better maintenance of hybrid and resistant varieties, better protection against pests and diseases, and keeping sufficient reserve stocks. Community-based approaches can result in marked cost savings for production of planting materials through economies of scale.

Community-based multiplication enables farmers to obtain hardened planting materials closer to the fields, and particularly effective for releasing and maintaining improved varieties, and controlling pest and disease infestations. The improvement in availability, access and quality of life sweet potato planting material that can be realized through the collaborative approach make it possible to distribute large amounts in a short period of time at the start of rainy seasons.

Multiplication of sweet potato through community-based organization can be done using basic materials that can be found locally, including tent-style greenhouse, fertilizers and disease control agents. Advanced multiplier set-ups involve assets like drip irrigation and other mechanized tools that reduce labor costs.

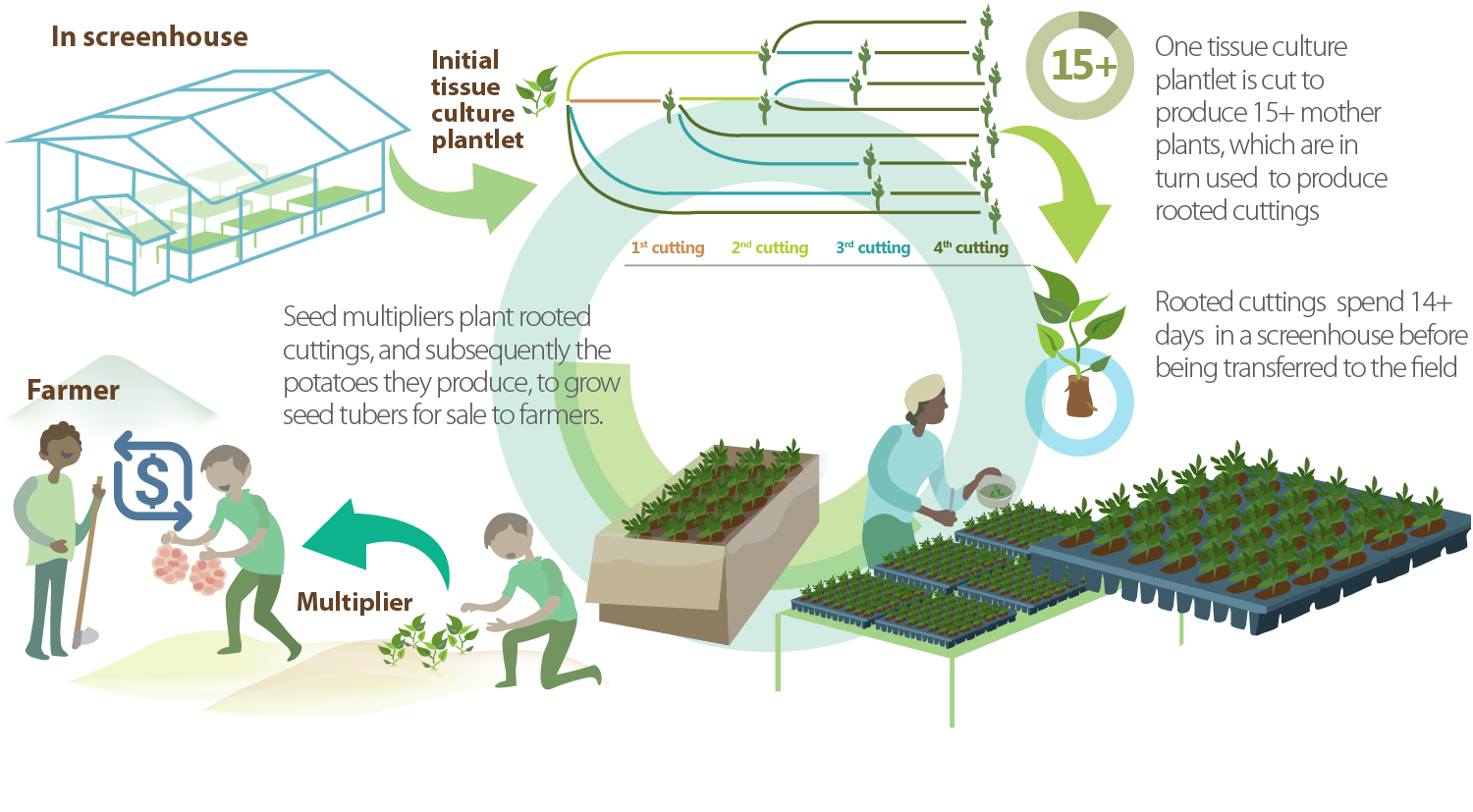

Public and private sector breeders produce tissue culture plantlets from improved varieties inside the laboratory that are subsequently cut into more than 15 mother plants. Community-based multipliers obtain a small number of the certified cuttings or seed potato from breeders which they subsequently use to grow rooted cuttings and vines in the screen house, altogether taking just over 14 days. Sweet potato multipliers are organized across a community based on the cultivation area and road connectivity, usually having sites for planting material multiplication dispersed at distances of 1 to 20 km.

Commercialization

Commercially available

Solution Images

Institutions

Accompanying Solutions

Orange-fleshed sweet potato (Bio-fortified, Drought and virus tolerant), Tent-style greenhouse production of vines and cuttings, Specialty blended fertilizers (high potassium),