Flour Milling and Blending Systems

Summary

Farmers and traders can add value by grinding wheat into flour that can be stored for several months and used to make a variety of processed food products such as bread, biscuits, cakes, porridges and pasta. Manual techniques for producing wheat flour are employed by many communities in Sub-Saharan Africa which do not provide large market opportunities because the quality doesn’t meet standards and preferences of consumers. Small to large sized milling and blending systems are available from local and international manufacturers that allow production of premium wheat flour close to production areas. The advantages of processing wheat into flour are the reduction in transport costs from farms to factories and the longer shelf life that result in better access and supply to markets, food processors and manufacturers at local and national scales. Building capacity in rural communities for milling and blending of wheat flour will boost the output, value addition and competitiveness of local producers, and will allow African wheat farmers to better rival with imported products.

About the Solution

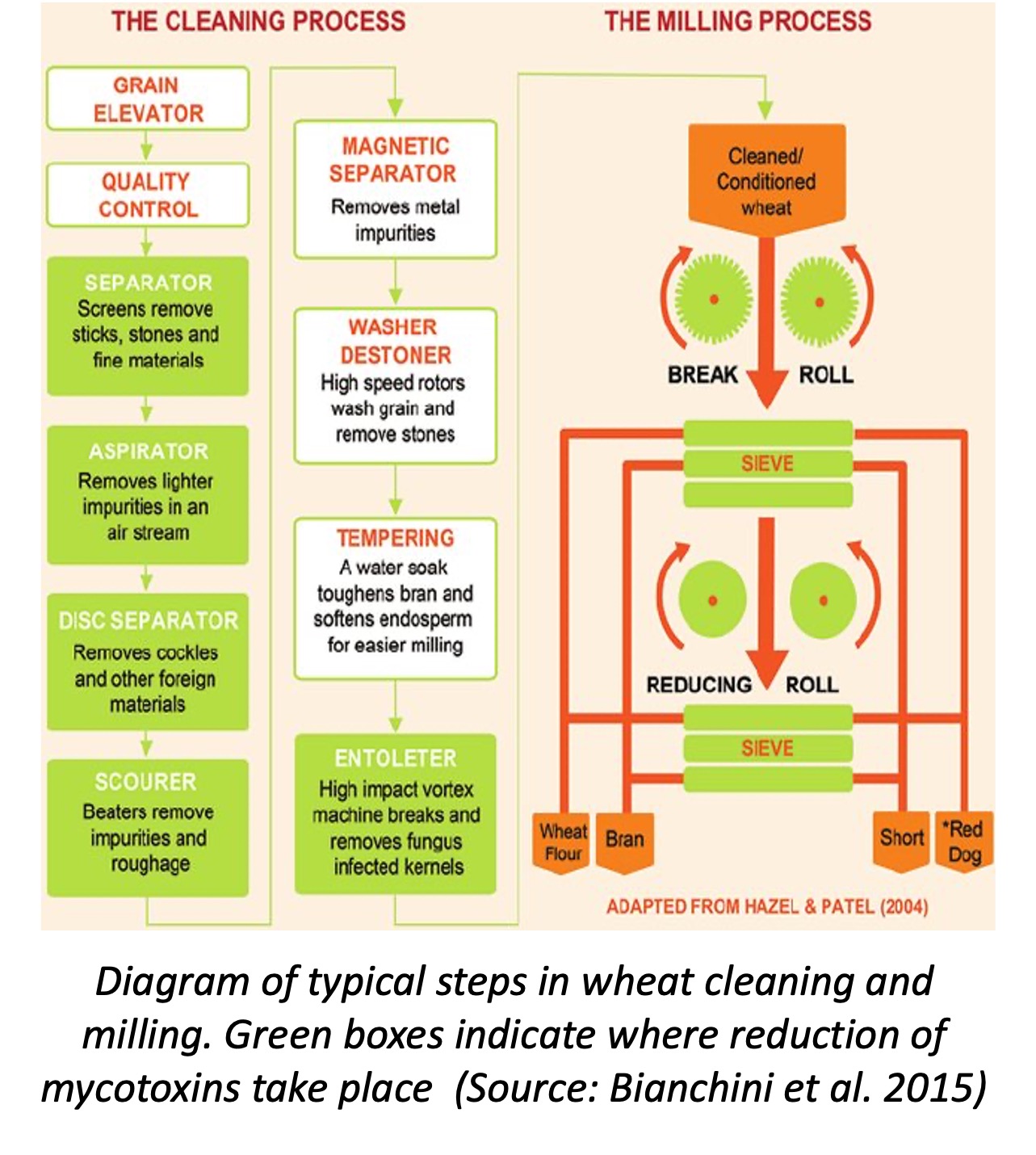

Producing wheat flour is an art which begins with selecting the right factory location, followed by procuring the right variety at the right price, and is concluded with cleaning, annealing and milling in the right manner. Locations for processing should be close to major growing areas that can provide reliable supply of quality biofortified grains, and have convenient transportation routes for easy delivery of raw grains and shipping of final product. In selecting the wheat varieties for blending it is important to take the hardness into consideration because it strongly affects the annealing time and may require using different silos for that step. Blending procedures must also be carried out in accordance with the gluten, sedimentation and index values that determine flour quality, and are closely monitored by food manufacturers. The purpose of annealing wheat is to ensure the optimum level of water for milling and enhancing the nutritional value, and the temperature and resting periods are crucial to wetting the wheat and distributing the water across the grain. Modern milling machines allow to obtain a very high proportion of flour out of wheat grains by sequential crushing of the grain, size reduction of particles and compression of flour carried out with a set of high pressure cast steel rollers that are specifically designed.

Flour milling and blending technologies for wheat allow to improve food self-sufficiency and promote business development in rural communities across major growing areas of Sub-Saharan Africa. Equipment setups with a small to large capacity are simple to install and can be supplied with electricity from the national grid, diesel generator and solar panels, making widespread deployment possible. The technology is particularly advantageous where there is limited access to storage facilities, poor road infrastructure and weak links with consumer markets and food processors. Milled wheat flour presents opportunities to improve existing supply chains and open up trade in new areas since it renders large savings on transport costs.

There is a wide range of equipment for cleaning wheat that perform specific processes based on size, shape and density of grains. A typical air-screen cleaner is made up of four screens that are located beneath a hopper. Grader machines that sort out impurities based on width and thickness are comprised of cylindrical screens that are horizontally positioned and have round perforations. Separators that select grains by length, density or gravity use angular sieves and forced air which can be adjusted according to specific needs. Annealing of wheat grains is done in resting basins or silos that are heated electrically or with natural gas. An abrasive grain mill has a feed-in hopper, roller table for grinding, rotary sieve for bran separation, and a compact engine and conveyor belt.

Before setting up a flour milling enterprise there is need for conducting deep market research to understand the needs and identify viable business models. If you are not sure about the location, it is advisable to consult a few experts so investments are not made at the wrong place. Next you need to make a comprehensive analysis of the investment needs for capital equipment, staff wages and other fixed and variable costs. Based upon this you can identify ways to finance the businesses, including loans and personal cash, and approach investors. Once funding is secured you can purchase the machines for cleaning, annealing and milling, and build the flour processing line based on professional advisory about optimal installation. Electricity is a very important spend in operation, and reducing its cost is key to making the investment profitable and maximize net margins. There is need for continuous quality assurance at the flour mill to make sure the product complies with market standards on gluten content, sedimentation and index values.

Commercialization

Commercially available

Solution Images

Institutions