Foliar micronutrient addition for healthier rice

Summary

Rice crops need a small but adequate amount of elements like magnesium, calcium, copper, zinc, manganese and boron to achieve high levels of grain yield and nutritional value. Availabilities of such micronutrient in soils are low across most rice growing areas of Sub-Saharan Africa (SSA) owing to the very old age and high weathering status of soils, along with insufficient replenishment through mineral fertilizers and organic resources. Spraying leaves and stems of rice crops with specialty liquid mixes of micronutrient fertilizer offers a practical and economical strategy to ensure rice crops have all necessary elements during critical growth stages. The technology doesn’t require elaborate investment or infrastructure, making that it can be easily adopted in rice growing communities of SSA. Incomes and profit margins from rice cultivation can be substantially raised by applying micronutrients onto the canopy of the crop since it renders larger harvests and more nutritious grain.

About the Solution

Micronutrients are mineral elements that crops need in small amounts to carry out essential metabolic processes such as photosynthesis and protein assimilation. Continuous or intermittent water logging of soils in rice paddies cause immobilization and leaching of magnesium, calcium, copper, zinc, manganese and boron that substantially limit availabilities for crops. External input of micronutrients via concentrated mineral forms is a powerful means to tackle deficiencies in agricultural fields, but their large price tag necessitates efficient delivery to crops for ensuring financial viability. Very high levels of plant uptake are achieved when micronutrients are sprayed on leaves and steams, which makes that much lower dosages need to be applied in comparison to when the same fertilizers would be placed in the soil. It is crucial micronutrient deficiencies in rice paddies are comprehensively analyzed on the basis of concentrations in soil, grain and stover to make sure farmers spray only those elements that are limiting and get the highest possible return. The different chemical make-ups of micronutrient fertilizers may cause interactions, which can be positive, neutral or negative, so appropriate formulations have to be used to achieve high levels of bioavailability, yield effects and nutrient use efficiencies.

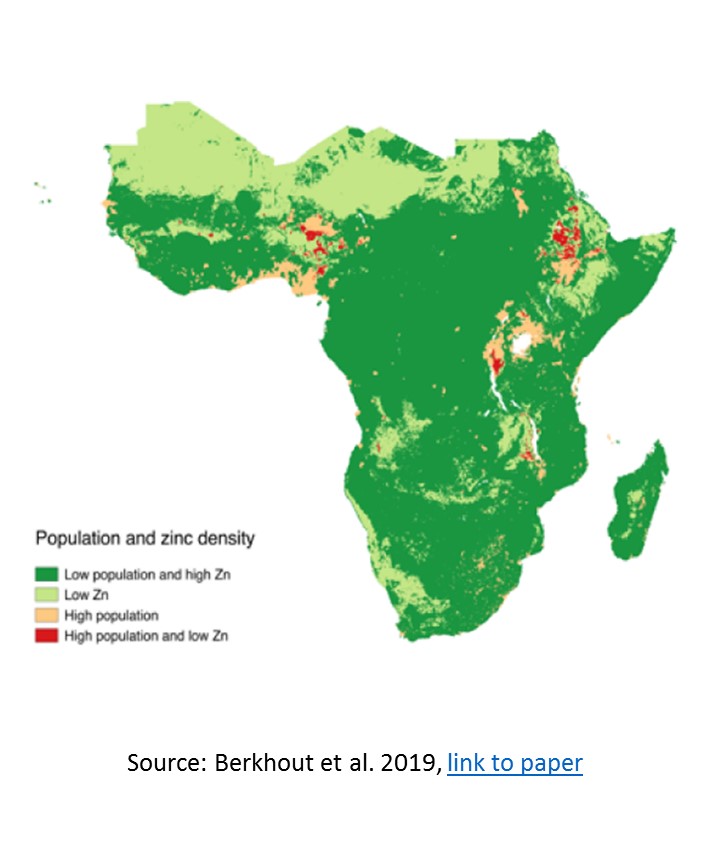

Foliar application technologies for micronutrient fertilizers can be implemented in any rice production zone of SSA because it is easy to adapt formulations and spraying methods for different agricultural and economic contexts. Many rice growing areas of Africa are plagued by micronutrient deficiencies, but the limiting element and underlying reasons are diverse, which makes that the practice has to be used in targeted fashion to increase yields and incomes of farmers. Available information on soil characteristics and population density allow identifying where there is a high risk of micronutrient deficiencies in rice production zone. This way, particular regions across the sub-humid savannahs of West and Southern Africa, and humid highlands of East Africa, have been distinguished that are prone to shortages of zinc, copper and manganese in food value chains.

Large agro-input suppliers are producing a large range of fertilizers with micronutrient such as zinc, copper, iron, boron and selenium for foliar application that have been specially designed to realize very high levels of uptake efficiency. The micronutrient fertilizers are either contained inside mineral salts with sulfates or ammonium, and silicates with oxygen, or organic chelating agents, which can be made into products with a single element, or a composite or blend of multiple elements. Most micronutrient fertilizer for direct applications onto the crop canopy are sold in a concentrated liquid form containing emulsifying chemicals that ensure a uniform delivery for maximal uptake. Some types of micronutrient fertilizer are sold as dry powder that have a longer shelf-life that liquid forms and need to solubilize in water by farmers.

Appropriate rates of nitrogen, phosphorus and potassium need to be applied in rice paddy field for micronutrient fertilization to successfully increase yields and incomes of farmers. Rice crops are typically sprayed with micro-elements starting from six to eight weeks after planting when the canopy of the stands has covered most of the soil, and then at critical stages of the production cycle like the onset of flowering and grain filling. Concentrated micronutrient fertilizers are first diluted by adding water up to the point that is recommended for rice crops; normally measuring between 50 and 150 gram per liter. A nebulizer sprayer that makes small droplets has to pass over the rice canopy at a distance of 30 cm distance for effectively and uniformly distributing solutions with micronutrient fertilizers. Knapsack sprayers can be used that are pressurized by hand and reach 1m of crop at a time, or fully automated sprayers for tractor mounting which can reach more than 10m. It is possible to add some types of liquid pesticides into the solutions with micronutrient fertilizers without negative side-effects between the two inputs. Spraying of rice fields is best performed when the crop is not in direct sunlight, and bees and other pollinating insects are not active; making sure no rain is predicted so micronutrient get fully absorbed by plants. Workers need to wear protective clothing, eye gear and mouth masks when spraying to avoid exposure.

Commercialization

Commercially available

Solution Images

Institutions

Accompanying Solutions

New Rice for Africa (NERICA), Hybrid Rice Varieties for Africa (ARICA), Mineral fertilizers with nitrogen, phosphorus and potassium