GEM parboiling and flour production for rice

Summary

Parboiling is a process whereby rough rice is steeped in cold or warm water, heated with steam under pressure or in boiling water to gelatinize starch with minimum grain swelling, followed by slow drying. The nutritional, flavor and textural characteristics of parboiled rice are better than non-parboiled counterparts and can match the quality of imported rice making it more appealing to consumers. Traditionally, parboiling is carried out in a cast iron drum with a false bottom for soaking and steaming that is placed on a three-stone fire, which is severely expose processors to air pollution from emissions of carbon monoxide and fine particulate matter (PM 2.5). A GEM parboiling system, i.e., “grain quality enhancer, energy‐efficient and durable material”, has been developed that incorporates a novel design of tank and stove that improves the process performance and quality as compared to traditional systems. These easy-to-build systems are highly suitable for small to medium scale processors in rice growing areas of Sub-Saharan Africa that have poor energy and market infrastructures.

About the Solution

The improved GEM parboiling systems drastically reduce the time needed for to steam the rice, allowing to complete the process in 20-25 minutes as opposed to 51-78 minutes for common artisanal technology. Parboiling increases grain translucency and decreases chalkiness due to starch gelatinization, and makes grains harder and less brittle as a result of the swelling of starchy endosperms during steaming that remedies preexisting defects. Food products made from parboiled rice have a low glycemic index which improves blood pressure and decreases risk of heart disease, a high fiber content that stimulates beneficial micro-organisms in the gut, and more available vitamin B as compared than non-parboiled rice. When carried out appropriately the parboiling process can bring locally produced rice close to the quality of premium imported rice. Turning rice into flour enables processor and traders to store it for several months which alleviate food insecurity and promotes widespread use of locally produced rice by food manufacturers in Sub-Saharan Africa.

The GEM parboiling system is suitable for all rice growing areas in Sub-Saharan Africa. Because it is made of simple materials and parts the GEM technology can be easily build and scaled in remote communities. Parboiling systems come in different sizes, with tanks for 20 to 100 kilogram of rice, and thereby allows processors to align the technology with their financial resources and throughput rates.

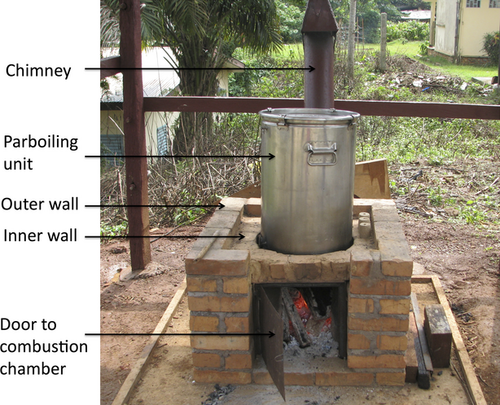

The GEM technology exists of a stainless steel parboiler tank with a cover for soaking and a stainless steel mesh basket for holding the soaked paddy that is placed inside the tank during steaming. The tank is closed using a tight‐fitting lid, which is not completely pressurized. The use of stainless steel for soaking and steaming is advantageous since it has good strength and is corrosion resistant. An improved stove system is used in the GEM technology, which has a cylindrical combustion chamber, a floor made from a single layer of fire bricks and walls with a double layer of fire bricks. There is a door on the combustion chamber to put wood, charcoal, or rice husk briquettes and allow air to come in. A chimney is fitted on top of the stove that promotes the flow of air and ensures that processors don’t inhale smoke. Stainless steel (Inox 18/8) needed for parboiler tank and steaming basket are commonly found on markets in Sub-Saharan Africa and the fire brick can be produced locally using kaolin rich clay.

Parboiling is carried out on rough rice with hulls that are first cleaned with a winnower and washed with water. Floating grains that have fissures are removed from the top and the rest carefully transferred into a clean container making sure that no sand and gravel that settled at the bottom goes with. Soaking of the rough rice is done by adding 2 parts of water per part of rice on weight basis and heating it up to 80°C before letting it sit under ambient temperature for 16 hours. The soaked rice is then put into a steaming vessel, which is put atop of the tank with boiling water for 20-25 minutes for vapor to pass through. Parboiled rough rice with hulls is dried in to sun up to 18% moisture content, and further in the shade up to 14% moisture content. Drying is best done on a tarpaulin atop of a cemented surface that is raised from the soil surface. After drying the parboiled rice is dehusked using a huller and polished using a roll mill. Grains are crushed and grinded into a fine powder using a dry rice flour mill. Packaging of rice flour can be done using paper or plastic bags.

Commercialization

Commercially available

Solution Images

Institutions

Accompanying Solutions

Improved rice varieties for Africa (NERICA and ARICA lines), Deep urea placement (nitrogen management), Foliar micronutrient addition, Engineered irrigation surfacing (and water lifting), Motorized weeders (cut and bury paddy weeds), RiceAdvice digital support