Hermetic Bags for Safe Storage of Beans

Summary

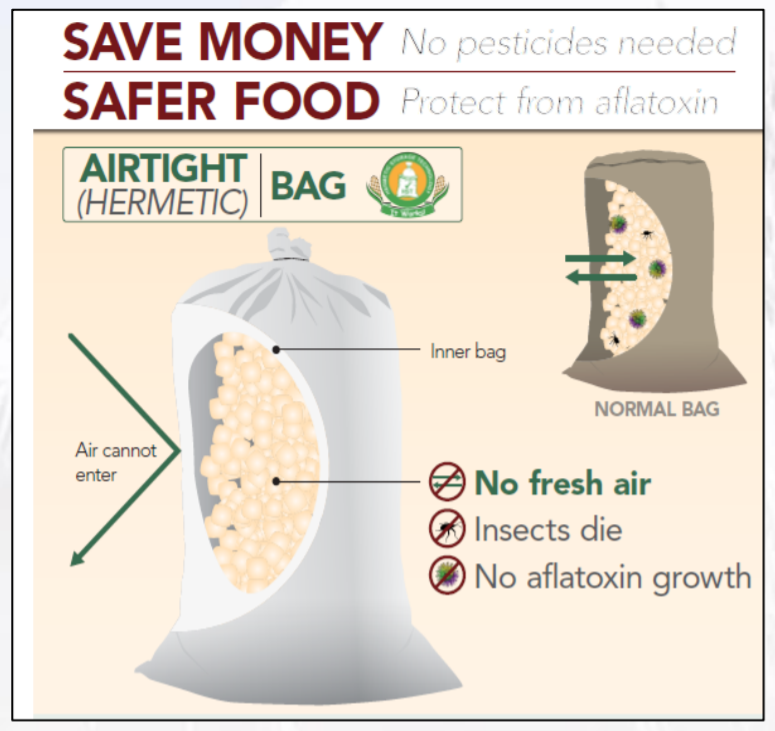

Large post-harvest losses of bean occurs across Sub-Sahara Africa because of improper storage techniques resulting in pest infestation that threatens the food security and livelihoods of farmers. As a result, farmers may opt to sell their produce immediately after harvest when market prices are at their lowest as a risk avoidance strategy. Grain storage pests such as weevils (bruchids) can be controlled by physical, chemical and biological methods. Some of the physical methods include use of hermitic storage bags and containers. The hermetic storage technology for grains avoids grain damage using sealed bags that prevents movement of air and moisture. The bags preserve the quality of grains and obstruct the entry of insects and microbial organisms through depletion of oxygen levels and accumulation of carbon dioxide. These conditions prevent damage by insects like weevils, moths and mites, curb development of fungi like aflatoxin that contaminate the grain, and maintain the taste and color characteristics of food. Hermitic bags allow for storage of grain without the need to apply chemicals.

About the Solution

Hermetic bags are air-tight which prevents oxygen and moisture from getting to the grain stored within them. A multi-layer technology is used to modify the environment and restrict gas exchange with the outside atmosphere. Under this system, farmers can store grains for up to two years while retaining their palatability and cooking quality. This ensures that farmers have enough to eat in between harvests and can sell their beans when the price is more favorable. Grain quality is conserved through the regulation of moisture inside the bag and inhibits fungal growth that lead to build-up of carcinogenic mycotoxins. The cooking time of grains preserved in hermetically sealed bags remains the same as freshly dried ones whereas loss of moisture in traditional storage techniques may double the amount of time and energy that is needed for preparing grains as food. A germination test is recommended for the beans stored in hermitic bags if they are intended to be used as planting material.

Storage of grains is particularly susceptible to damage by insects and microorganisms under the hot and humid weather in Sub-Saharan Africa because these conditions promote the multiplication of pests. Losses of more than 25% in storage are common because current bagging and silo techniques of farmers, traders and food manufacturers do not provide ample safeguards to exclude and inhibit pests. Hermetic storage bags are well suited to the operations and infrastructure of both small-scale and commercial growers and processors, and the low cost of storage bags and ability to reuse these for several years are another advantageous feature of their use. This grain preservation technology is especially suitable in regions where the transportation infrastructure is poor, and where markets and processing industries are distant, as is the case across many bean production areas. Hermetic bags are becoming widely available across Sub-Saharan Africa. To date, the storage technology has been introduced, piloted, adopted and now commercialized in countries not limited to Kenya, Ghana, Uganda, Ethiopia, South Sudan, Niger and Burkina Faso through various programs and interventions.

Hermetic storage bags have several protective layers with two separate inner liners made of high-density polyethylene with a thickness of about 0.8 mm and a polypropylene woven bag on the outside. A sealed environment is created by the inner bags that have very low permeability of gasses and are water-repellent, allowing it to maintain stable moisture levels in stored grains under both dry and humid external atmospheric conditions. The outer bag provides strength to withstand handling and is adjusted to the weight of the grains it contains. A series of hermetic storage bags are marketed by different brands including the Purdue Improved Crop Storage (PICS), ZeroFly Storage Bags, Elite Storage Bags, GrainPro Storage Bags, and AgroZ Storage Bags.

Threshed grains are dried to an appropriate moisture level and then placed into high-density polyethelene bags with a capacity of 50 kg or 100 kg. The first bag is filled completely, but with a 20-30 cm neck allowance, and tied securely. The second bag’s neck, surrounding the inner bag containing the beans, is also tied securely. Finally, these two bags are placed in a third woven nylon or polypropylene bag. With the third bag tied securely, the container can be handled without bursting the inner bags and is readily accepted by grain buyers and handlers. An alternative method is to fold both liners together and twist tie them together, an approach that considerably reduces time spent on bag sealing.

Commercialization

Commercially available

Solution Images

Institutions