Hermetic Bags for Safe Storage of Wheat

Summary

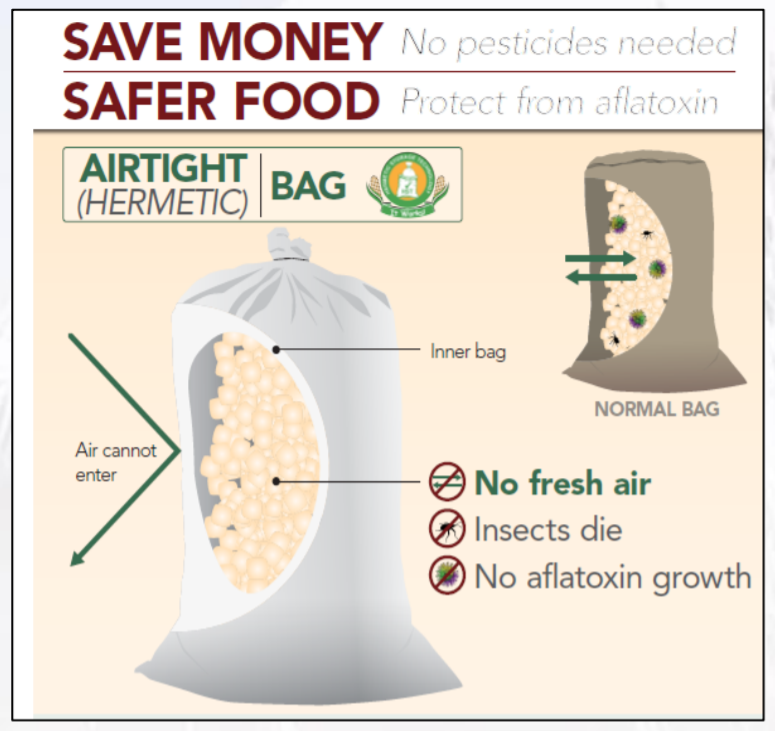

Large post-harvest losses of wheat grain take place in Sub-Sahara Africa because of improper storage techniques and pest infestation which gravely affect the food security and livelihoods of farmers. To avoid this risk grains are immediately sold after harvest by farmers when market prices are at their lowest. The hermetic storage technology for grains allows to overcome this challenge by using sealed bags that prevent air and moisture from getting into them. The bags preserve the quality of grains and obstruct the entry of insects and microbial organisms through depletion of oxygen levels and accumulation of carbon dioxide. These conditions prevent damage by insects like beetles, weevils, moths, mites and borers, rule out development of fungi that contaminate the grain, and ensure taste and color characteristics of the food product are maintained. This simple and inexpensive storage technology make it possible for farmers to improve the year-round supply of food and income.

About the Solution

Hermetic bags are air-tight which prevents oxygen and moisture from getting to the grain stored in them. A multi-layer technology is used to modify the environment and restrict gas exchange with the outside atmosphere. Under this system, farmers can store grains for up to two years while retaining their palatability and cooking quality. This ensures that farmers have enough to eat in between harvests and can sell their wheat produce when the price is more favorable. Grain quality is conserved through the regulation of moisture inside the bag and inhibits fungal growth that lead to build-up of carcinogenic mycotoxins. It has been showed that the cooking time of grains that have been preserved in hermetically sealed bags for six months is the same as freshly dried ones whereas loss of moisture in traditional storage techniques doubles the amount of time and energy that is needed for preparing the food.

Storage of grains is particularly susceptible to damage by insects and microorganisms under the hot and humid weather in Sub-Saharan Africa because these conditions promote the multiplication of pests. Losses of more than 25% in storage are common because current bagging and siloing techniques of farmers, traders and food manufacturers do not provide ample safeguards to keep pests out. Hermitic storage bags fit right into the operations and infrastructure from commercial and small-scale growers and processors, and the low cost of storage bags and ability to reuse these for several years are preferable for each of these actors. This grain preservation technology is especially suitable in regions where the road network is bad, and where markets and processing industries are located far away, like is the case across major wheat growing areas on the continent.

Hermetic storage bags have several protective layers with two separate inner liners made of high-density polyethylene with a thickness of 0.8 mm and a standard polypropylene woven bag on the outside. A sealed environment is created by the inner bags that have very low permeability of gasses and are water repellent, allowing it to maintain stable moisture levels in stored grains under both dry and humid conditions of outside air. The outer bag provides for strength to withstand handling given the weight of the grains it contains. A series of hermetic storage bags are marketed by different brands including the Purdue Improved Crop Storage (PICS), ZeroFly Storage Bags, Elite Storage Bags, GrainPro Storage Bags, and AgroZ Storage Bags.

Threshed grains are dried to appropriate moisture level and then placed into high-density polyethelene bags with a capacity of 50 kg or 100 kg. The first bag is filled completely, but with a 20-30 cm neck allowance, and tied securely. The second bag’s neck, surrounding the inner bag containing the bean grains, is also tied securely. Finally, these two bags are placed in a third woven nylon or polypropylene bag. With the third bag tied securely, the container can be handled without bursting the inner bags and is readily accepted by grain buyers and handlers. The hermetic bagging process can be performed entirely by hand or fitted into automated fill and seal machines. Wheat grain can be stored for up to 2 years with this preservation technology. Rats, mice, squirls and other rodents are able to chew through the different layers, breaking the hermetic protective environment, and thus have to be kept away from stored bags.

Commercialization

Commercially available

Solution Images

Institutions