Hide Curing and Secondary Leatherworks

Summary

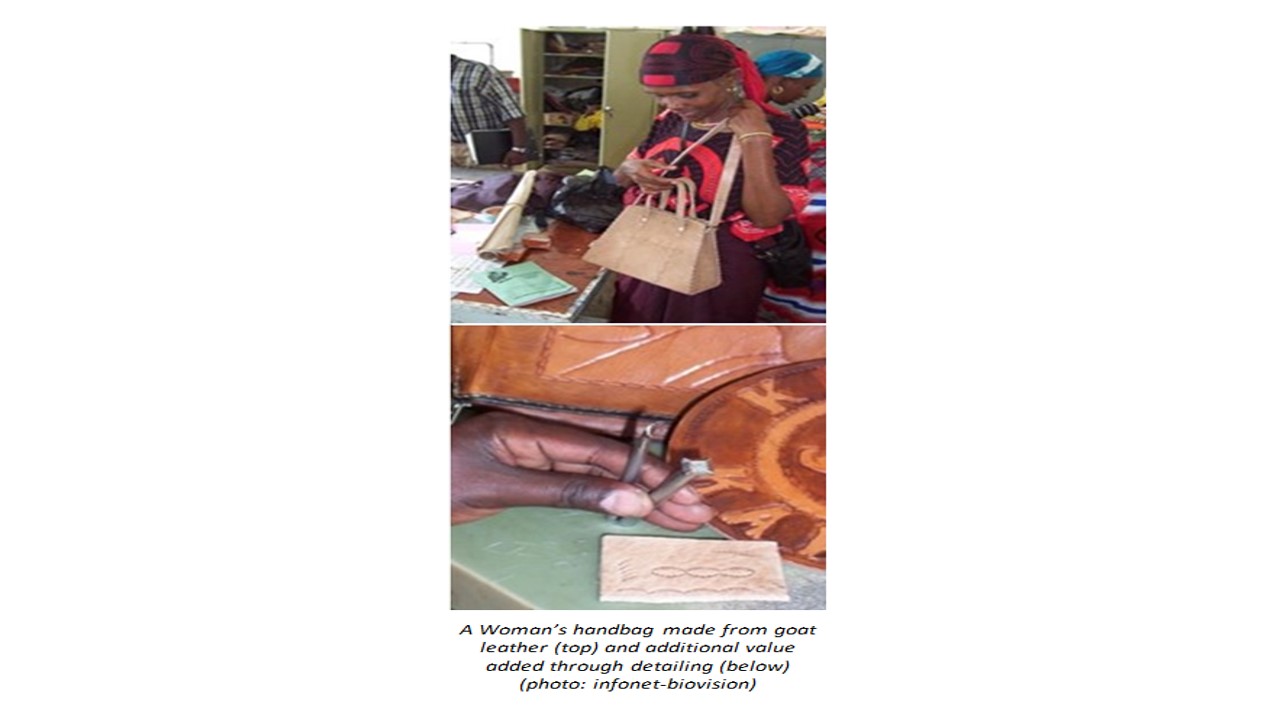

Other than the carcass for meat, hides are the next most valuable product from livestock production. For this value to be realized, animals and their hides must be properly treated, and artisans require skill sets and appropriate materials. Value is lost when hides are cut and served as food with the carcass. Alternatively, hides are processed by local communities, stockpiled, sold, and fabricated by leatherworks industries into a variety of products for both domestic and export markets. Foremost among those products are shoes, handbags, and leather clothing, with premium value obtained through greater craftsmanship.

About the Solution

Depending on the intended use, animal hides are cured in ways that either retain or remove the hair. The raw hide is carefully removed from the carcass, scraped clear of any remaining flesh, treated with salt or brine, and stretched across a rack until dry, a process requiring between 7 to 30 days depending on the weather conditions. Salt pulls moisture from the skin and prevents flies from laying eggs that later result in putrefaction. After drying, hair may be removed by scraping, and then marketed for forward processing. Another, more advanced approach to curing involves initially soaking the hide in a solution of hydrated lime for 24 to 36 hours, de-liming in an ammonium sulfate solution (or vinegar) overnight, and then washing several times in clean water before stretching and drying. Tanning results in relaxing and stretching the hide and preservation, often through treatment with alum and tannins. Once tanning is completed, the skins are washed a final time and subjected to final stretching and scrapping while drying, resulting in a smooth and pliable finish. Note that several African trees, particularly Acacias are rich in tannin and used in more traditional applications. Bleaching, polishing, and oiling are additional processes that can enhance leather utility and quality.

The curing of hide and secondary processing into leather is a common practice of pastoralist communities in Africa such as the Maasai in Kenya and Tanzania, the Fulani in northern Nigeria, Niger and Chad, the Peul and Fula in Mali and the Sahelian Tuaregs reaching as far north as Senegal and east as Chad. Their main leather products include pouches, sheathes, wallets, belts, tapestries, and rugs; all used in local communities, domestic trade, and export. Ethiopia and Kenya have advanced industries producing quality shoes for regional markets. Greatest value occurs when these products enter into the tourist trade.

The skinning knife is a very sharp knife that is used to peel away the hide from the carcass. The tanner knife as it is commonly known, is the primary tool for fleshing, dehairing, scudding and frizzing hides. This tool scrapes away membrane, fat and excess meat from the hide to ensure it will properly tan. A pair of rubber boots, an apron and elbow-long gloves are needed to protect against harsh tanning chemicals and cuts from sharp knives.

A realistic starting scale is the treatment of 10 to 20 hides at a time in 100-liter brining and tanning containers, relying upon as little as five chemicals and hand labor. Personal protection consists of plastic gloves, waterproof aprons, and boots.

Commercialization

Commercially available

Solution Images

Institutions