High quality cassava flour and industrial starches

Summary

Fresh cassava roots are very quick to perish and mold because of their high water content, thereby posing a major challenge for farmers to store the food or sell it on markets. African communities growing cassava have always been processing the roots in one way or another to extend the shelf life and eliminate toxic cyanide compounds. The techniques that are traditionally used for producing cassava flour do not provide significant market opportunities to the smallholder cassava farmers. High quality cassava flour (HQCF) is made through a series of steps, but is not fermented like fufu or gari, making it odorless and giving it a white or off-white color. The main advantages of processing fresh roots into HQCF are the reduction in transport costs from farms to factories, and the longer shelf life of the raw food product. HQCF and derived starches are suitable for manufacturing a wide range of foods and goods, and substitutes imported wheat or other sources of starch. Building capacity in remote rural communities for production of HQCF and starches will boost the performance, value addition and competitiveness along the entire cassava value chain, and thus give rise to societal and economic progress.

About the Solution

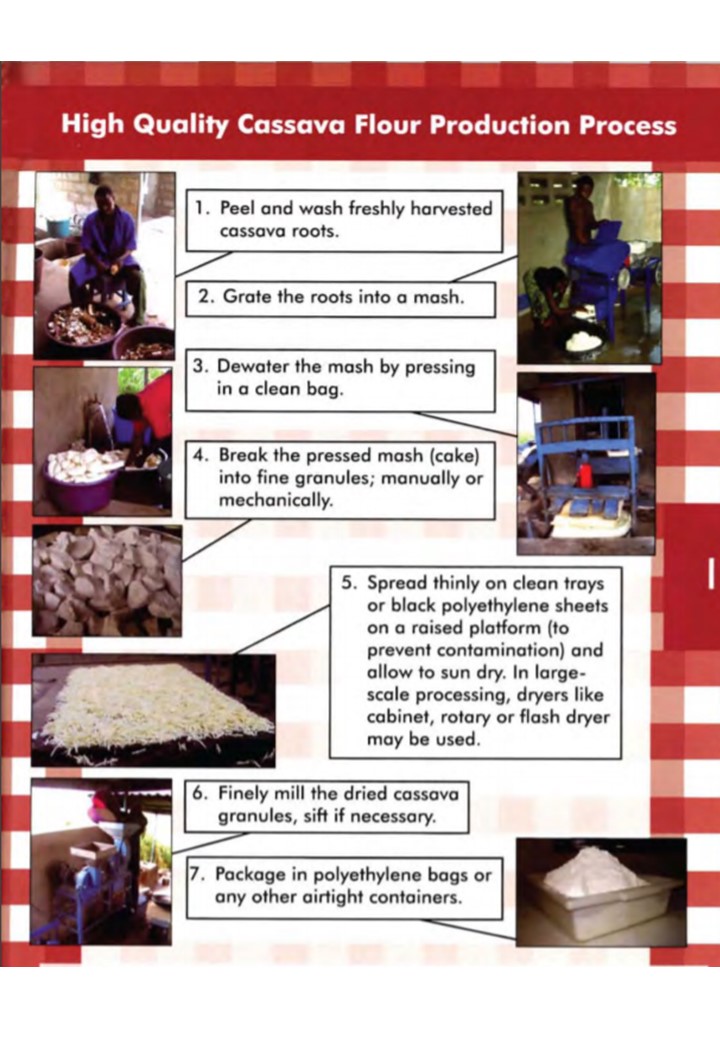

Manufacturing HQCF is done using fresh roots with high dry matter and starch content, and low levels of bitter tasting cyanides, and needs to take place within a day or two after harvest so the desired quality is obtained. The key steps in producing HQCF are: raw material selection, peeling, washing, grating, pressing, disintegration, sifting, drying, milling, screening, packaging, and storage; though slicing or chipping can be performed instead of grating, pressing, disintegration and sifting. Detoxification of cassava roots in this process happens through grating, dewatering, and drying that unlike fermentation do not result in a bitter taste and odor. Extraction of starch from cassava follow a similar process expect that it requires wet milling of grits or chip and physical separation of fibers. To achieve a high degree of palatability and starch content in the flour product it critical that fresh cassava roots get delivered on time and are processed with appropriate methods, for which capacity needs to be built within farmer communities. HQCF is a gluten-free product, making it ideally suited for manufacturing of non-allergenic foods which a major growth market globally.

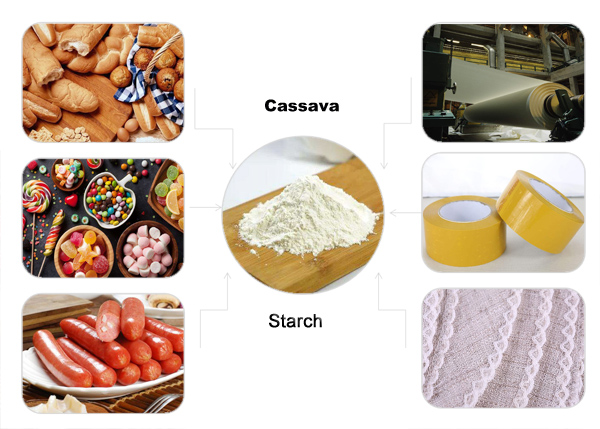

HQCF is suitable for manufacturing a large range of food product, such as soups, bread, glucose syrups and alcohol. The proportion of HQCF that can be used in bakery products amounts from 10% to 35%, and the heavy cake structure bread is preferred in rural areas. Through the use of enzymes from plant seedlings it is possible to convert of HQCF into sugar syrups which are similar to common dextrose products and meet different end-user requirements. In further steps, the sugar syrup derived from cassava can be made into alcohol for potable and industrial use. When blending HQCF with salt and soda it can be used as adhesive for paper board and plywood glues, and extracted starches as filler for cosmetic, pharmaceutical and regular products, or as textile stiffener; completely replacing imported starch materials derived from wheat and other crops.

Nutritional and chemical properties of HQCF or derived starches are depending on the used cassava variety, freshness of roots and processing steps; all of which have to be harmonized with the customer requirements. The typical quality standards of HQCF are: moisture content 13%, fiber 2%, ash 3%, fine flour (<0.6 mm) 90%, hydrocyanic acid 10 mg/kg, sulfated ash 0.5%, starch content 65 - 70%, protein content 1.3 - 2.0%, crude fat content 0.3 - 0.5%, and total acidity 1%. Pro-vitamin A or beta-carotenoids levels measure 0.06 μg/g for HQCF that is made from white fleshed cassava, whereas this goes up to 10.7 µg/g when biofortified yellow fleshed cassava is used to prepare HQCF. The moisture content of flour determines its storage stability, as the lower the flour moisture, the higher the storage stability. The cyanide content for HQCF is very low (2.04 to 48.13 ppm) and within safe level for human consumption. Foaming and emulsion capacities of HQCF is low but its bulk densities, water and oil absorption capacities as well as degree of gelatinization are high.

Manufacturing of HQCF can be done with simple cottage style equipment that are manually operated, similar to that already used for gari processing. Large automated systems are available for industrial scale processing of cassava roots into flour. The minimal infrastructure required for manufacturing of HQCF include: a grater for size reduction, press for dewatering, solar or flash dryer for drying, pin mill for comminution and stitching machine for packaging. For production of starch there is need to remove cellulose fibers that were released in the wet milling step, which can be done with a jet extractor or perforated-basket centrifuge. Reliable supply of low-cost electricity from the national grid, diesel generators or photovoltaic panels has to be in place for warranting uninterrupted and cost-effective manufacturing of HQCF and starches.

Commercialization

Commercially available

Solution Images

Institutions

Accompanying Solutions

Golden cassava varieties, Cassava varieties with high dry matter and starch content, Mobile cassava processing plant