Induced Ripening of Banana for Increased Marketability and Storage

Summary

Banana ripening is a combination of physiological and biochemical processes resulting in changed color, sugar content, texture and aroma. Dessert bananas are most often harvested prematurely to reduce injury during transportation. Bananas may be artificially ripened using different chemical agents, most often ethylene gas. Commercial ripening chambers control temperature, humidity, and ethylene gas concentration. Catalytic generators are used to produce ethylene for induced ripening, with concentrations of 100 ppm for 12 hours having immediate effect. Acetylene serves as an ethylene analogue. Ethephon is a widely used compound that releases ethylene. Fruits artificially ripened have a similar yellow color and taste to those naturally ripened. This is not the case for bananas ripened by more traditional methods such as burning leaves or kerosene

About the Solution

Plantain and banana suffer major post-harvest losses due to poor damage during transportation. This is particularly the case for dessert banana that are generally purchased in a ripened state. Traditionally, bunches are ripened by wrapping green leaves around them, requiring up to two weeks and resulting in non-uniform results. Ripening of the fruit can be slowed down or accelerated by adjusting the temperature and humidity as well as by providing a targeted supply of ethylene gas and regulating the CO2 concentration. Artisanal and industrial chamber systems for ripening are available. This induced ripening reduces the protein content and increase sugar in most banana varieties.

The location of ripening chambers should be close to the target market, be easily accessible, and have reliable supply of key materials and energy. Fruit growers have the challenges of getting their produce ripened at the required time so that they can sell immediately. Fruit sellers want to serve a clientele of customers with ready-to-eat banana every day so that they do not move from stall to stall in search of their preferred fruits. For this reason, it is important that they devise ways and methods which will help them guarantee their customers of the fresh fruit as and when they want them.

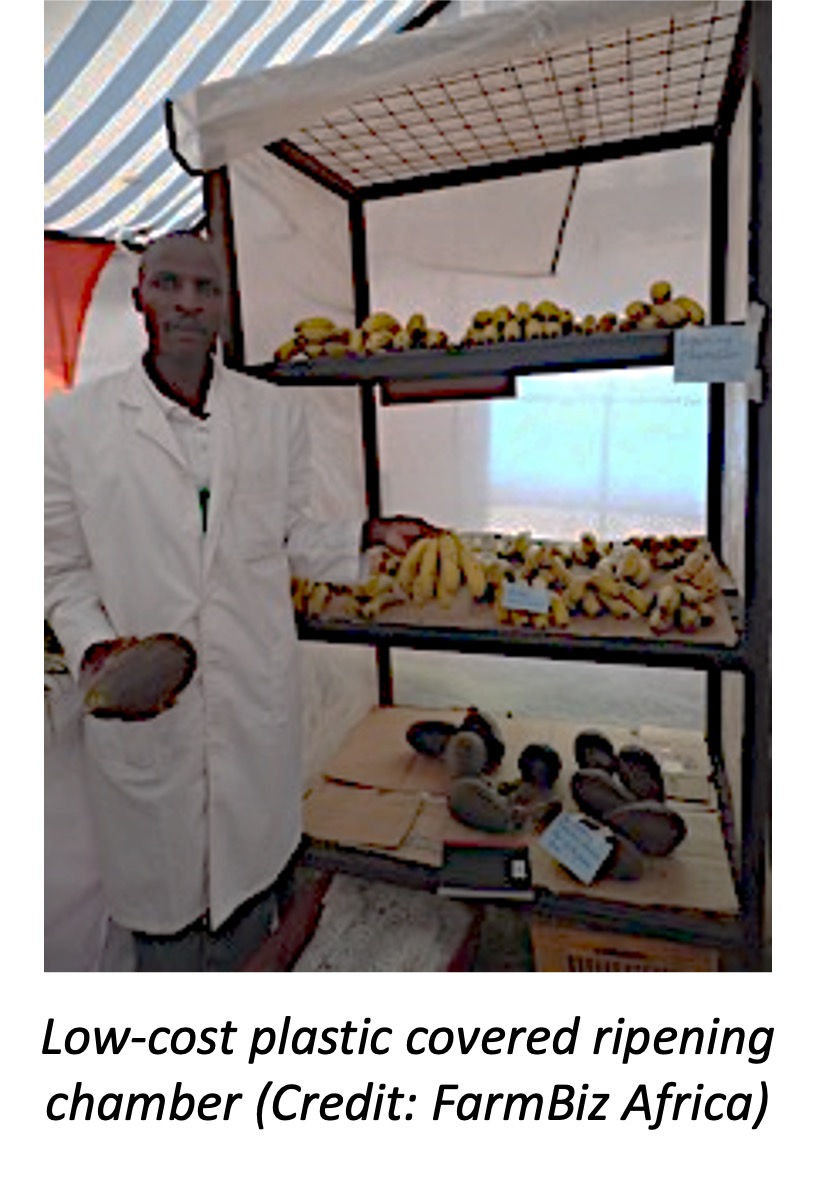

Low-cost ripening chambers are constructed with metal or wood frame and covered with thick plastic sheet to make it airtight. As catalyst, avocados and passion fruit are added to bottom shelve of the chamber since these fruits release lots of ethylene. More advanced industrial ripening chambers are composed of insulating chambers, refrigeration system, humidifier, ethylene generator, gas analyzer and a control panel.

Ethylene is introduced by generating chemicals such as Ethephon (Trade name Ethrel, 2000 ppm dip for 3 minutes). For best ripening results, humidity should be 90% to 95% to prevent moisture loss. In simple passive closed chambers, this is achieved using basins of water, and in industrial-scale rooms this is achieved using humidifiers. Quick ripening is requires temperatures of 18-20°C within 4 days, slower ripening lower happens at lower temperature (14-16°C) takes 8-10 days.

Commercialization

Commercially available

Solution Images

Institutions