Mechanized Defeathering and Egg Sorting

Summary

After slaughtering chickens for meat, they require scalding and defeathering, before cutting the carcass. When done manually, this step is time-consuming, reducing output, and posing serious occupational hazard to workers. Grading eggs to specified weight, size and color is also labor-intensive and inaccurate when performed by hand. Mechanized defeathering and egg sorting systems are commercially available for smaller scale farm enterprises that increase throughput and improve product quality. When chicken reach target weight it is critical to process them quickly as the productive gain and feed efficiency decline. Defeathering equipment allows producers to quickly process chicken without damage and avoid rushed sales at a lower price. For eggs, different grades are demanded by hotels, restaurants, confectionery industries, and bakeries according to weight and color. Egg producers benefit from speedy, reduced handling costs and attracting premium prices for their highest-grade eggs. Mechanized sorting distinguishes grades faster and better than manual approaches, ease packaging and transportation, and reduce losses due to breakage.

About the Solution

Defeathering, also known as plucking, is the removal of feathers from carcasses. After chickens have been slaughtered, and the blood completely drained, the carcasses pass through a series of steps for removing different sets of feathers. The body is first submerged in hot water at 60°C for 2 minutes. Once scalded, the chickens are placed into a defeathering machines. These can typically handle four or ten chickens at a time, and the feather removal process is completed in only 30 seconds, whereas manual plucking typically takes several minutes per chicken. The removed feathers come out at an opening below the machine. Defeathered chicken are then passed on for evisceration where internal organs are removed. Systems for egg sorting are equipped with different sets of sensors that detect specific quality parameters like weight, color, shape, and cracks. Usually, a tubular lamp is fitted on the table so operators can see eggs that are “candled” while handling the infeed and packing. Egg graders consume little electric power and have very low maintenance costs.

Defeathering machines handle a wide range of poultry such as cockerels, broilers, turkeys, and old layers. Simple plucking drums that can handle one to five chickens at a time are available for small and medium scale poultry producers. Egg sorting machines are versatile and can be used for any type of small bird like hen eggs, quail eggs, duck eggs and goose eggs. Different configurations of graders suit different needs and demands, with lower capacity machines being ideal for small free-range layer chicken farmers.

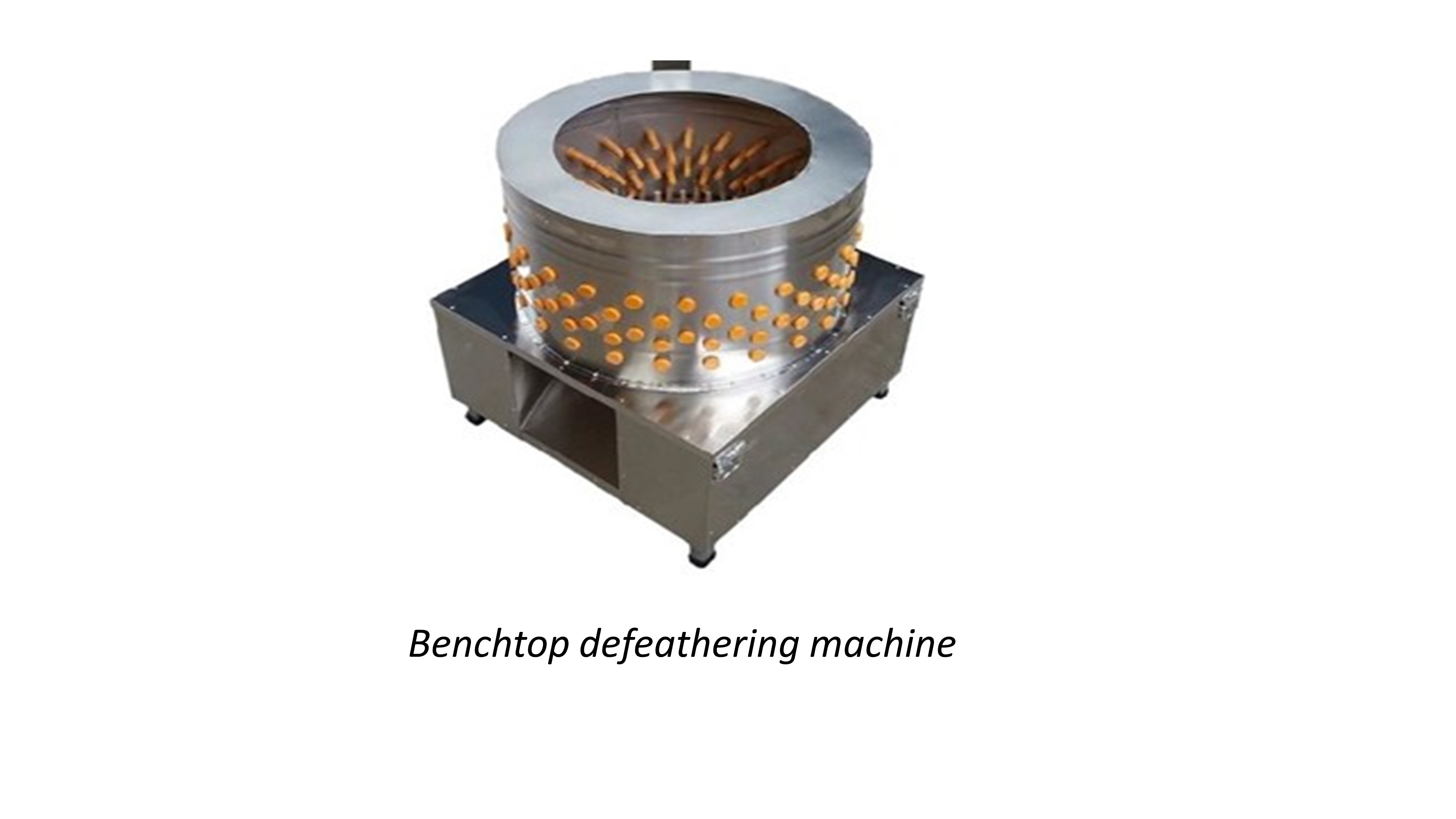

Most defeathering machines are made of a drum that is fitted with multiple high-speed rotating metal discs that bear rubber fingers. The movement of these protruding parts over the body removes the feathers. Egg sorting machines are made of a series of weight sensitive belts that allow eggs to roll onto spaces to received eggs of different grades. The calibration of these belts determines the sorting and thus a critical part of operations. Egg sorters may be coupled with collectors in cages and box loading machines for full automation.

The capacity of the defeathering and egg sorting machines must be matched with the flock size and production line specifications. Both technologies require well-trained staff, and adequate water and electricity supply are required. Specialty slaughtering equipment are required to minimize animal suffering and keep meat safe. Once defeathered the whole chicken is coated to improve preservation or moved to a filleting line. A fridge or freezer is needed to safely store the meat. For eggs, after collection they are first washed using an odorless detergent solution with cool water to prevent it from moving through the shell. It is common practice to spray eggs with food-grade oil to reduce moisture loss and bacterial growth. Processing equipment is made of stainless steel and must be cleaned regularly for maintaining quality standards and prevent adulteration with foreign materials.

Commercialization

Commercially available

Solution Images

Institutions