Pre-Cooked Beans for Consumer Convenience

Summary

Common bean is a major staple food in eastern and southern Africa, the second-most important source of human dietary protein and the third-most important source of calories. Yet the sale and consumption of whole dried common beans is discouraged by their long cooking time, and high energy and water requirements. Pre-cooking combined with canned or frozen preservation techniques substantially decreases preparation time and fuel use, making it more attractive to urban and middle-class consumers and creating a growing commercial opportunity. This technology not only improves food and nutritional security but also the income of farmers by stimulating demand and opening up access to higher-value markets. Pre-cooked products further strengthen the common bean value chain in Sub-Saharan Africa, offering greater marketability and profit margins. Women homemakers and canteen caterers especially benefit from the time savings to prepare meals with beans as they are freed up to do other more productive activities.

About the Solution

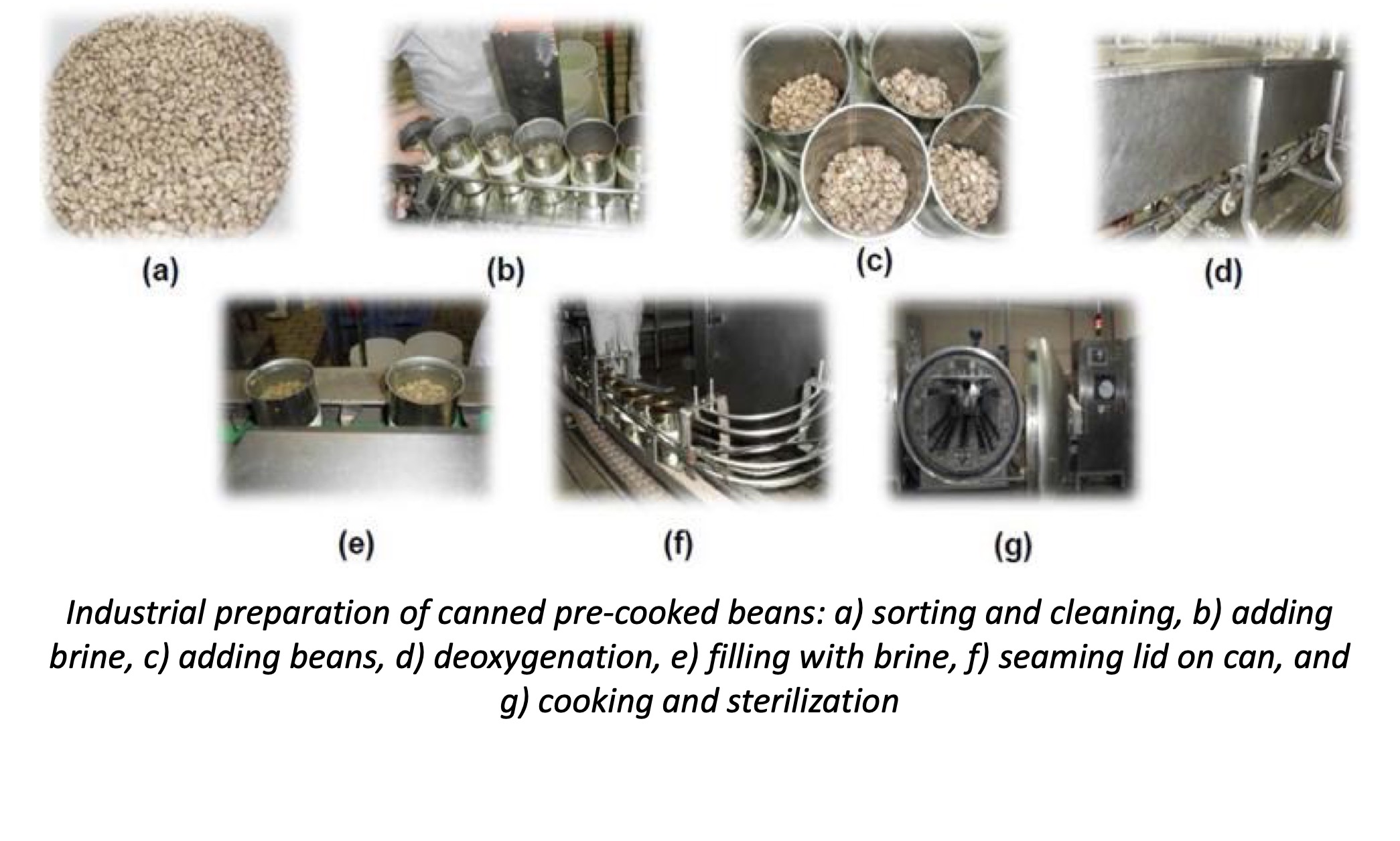

Pre-cooked whole beans come as dried, canned and frozen products which can be prepared in only 10 to 30 minutes, saving over 1.5 hours of cooking time, eliminating the need for soaking and hugely reducing fuel expenditure. The process of making pre-cooked beans starts with sorting, washing and sizing for which air and water is passed over the food product. This is followed by blanching at 95°C for 3 minutes, soaking at 45°C for 120 minutes, sterilization and cooking of hydrated beans at 97°C for 120 minutes, and drying at room temperature for approximately 24 hours. Beans are then packaged and frozen. Processing of canned beans involves the same soaking, blanching and cooking procedure which is followed by brine addition, cooling, canning and labeling. Pre-cooked frozen and canned beans can be commercialized for both local and export markets.

The pre-cooking technology for whole beans is ideally suited to make nutritious diets more widely available to consumers. It serves as a way for marketing biofortified bean varieties with higher iron and zinc levels to middle-class urban populations that are decreasingly reliant upon beans. This food processing technique can be implemented by artisanal and industrial enterprises as simple low-cost equipment setups are required. Frozen pre-cooked bean products require cold chain storage and transport, reliable delivery infrastructure and strong links with markets.

High-quality soft-cooking varieties of common bean with appealing taste and color should be used for this processing technique, such as is the case with NABE 4, NABE 14, Rosecoco and Wairimu in Kenya and Uganda. The equipment needed for producing pre-cooked beans includes sorters for color grading, sieves and screens for removing stones and woody stems and shells, baths for washing and soaking, and vessels for boiling which are available as manual or automated systems in different sizes and that draw power from wood fuel, natural gas or electricity.

Selecting common bean varieties for pre-cooked products that meet the dietary preference and culinary practices of consumers is based upon a series of factors such as ease of growing, preparation time, color and micronutrient content. Farmers operating as out growers for processing facilities require access to quality seed, fertilizer and other accompanying inputs to ensure adequate supply of whole beans. There are a number of ways to achieve this which have proven very efficient for the commercialization of pre-cooked bean products in Kenya and Uganda. Among the most popular schemes are the seed credit model involving contracts with loans that are amortized in cash from sales to processors, and the revolving seed model where credit gets repaid through delivery of whole grain. Preparing frozen products typically involves cooking very large batches of whole beans whereas for canned products this step is done inside metal tins as it eases the work and improves food hygiene. Different models can be employed such as collective enterprises with a single common processing plant, or pooled enterprises with multiple small plants at separate locations.

Commercialization

Commercially available

Solution Images

Institutions