Seed dressing of Seed with Fungicide and Insecticide

Summary

Attacks of common bean by fungal diseases such as anthracnose, damping off or root rots, and insect pests like stem maggots are responsible for large yield losses in Africa. Control measures against these pathogens have to be taken early on in the season for avoiding damage of common bean crops. The small gains in common bean yields across Eastern and Southern Africa that were made over the past 30 years despite an increase of the cultivated area is in large part attributed to diseases and insects. Such infestations also pose major risk to the profitability of improved varieties and fertilizer inputs by farmers. Dressing seed of common bean with chemical control agents for diseases and pests offers a cheap and environmentally friendly technology to prevent losses and enhance production. The seed treatment approach uses minimal amounts of pesticides and results in better seedling emergence that in turn strengthens the resistance of crop stands throughout the growing season.

About the Solution

Common bean diseases such as anthracnose, bacterial blight and angular leaf spot, and insect pests such as bruchids are harbored by seed, and lead to destruction of planting material stocks and potentially affect large areas of farmland. On the other hand, soil-borne diseases like wilts, rots and rusts, and insect pests like bean stem maggots plague seedlings of common bean which can lead to sparse plant density or even total crop failure. The technique of seed dressing makes it possible to keep common beans free of these diseases and pests during seed storage and seedling emergence. Use of seed dressing achieves a very high degree and efficiency of crop protection since it guarantees uniform application of control agents and delivers these where they are needed most. In this way the method minimizes undesired effects on non-target organisms in soils and spillage of chemicals into water bodies such as is the case for broadcast spraying of crop stands. The advantage of seed dressing is that it doesn’t require specialized equipment and can be easily performed at farms and factories, making it a solution that can be widely adopted.

Seed dressing technology for fungicides and insecticides is strongly recommended in all major production areas of common bean due to the high prevalence of diseases and pests. Seed dressing products such as Syngenta’s APRON STAR® contain a fungicide and insecticide mixture for controlling fungal diseases (e.g. Pythium and Fusarium) and early season insects pests (e.g. stem maggots, termites, thrips and whiteflies) including ones that serve as disease vectors. As a result, root development is stimulated leading to vigorous starts, uniform growth and higher yields. Benefits continue for about three weeks after planting. The approach is very suitable for tropical regions with cool and humid climates that favor the proliferation of fungal pathogens. Control agents for a large number of pathogens can be coated onto seed in ways adjusted to which soil type and pest and disease conditions. Fungicide and insecticide seed treatment lies at the foundation of precision agriculture and integrated pest management, contributing largely towards sustainable intensification and strengthening resilience of common bean.

Control agents for seed dressing are sold in both liquid and dry formulations. Combinations of different chemical substances can be used for seed treatment based on guidelines provided by the suppliers and should not be confused with products intended to protect bans during storage as food. The most common broad-spectrum fungicides for seed dressing are tetramethylthiram disulfide and N-trichloromethyl-thio-4-cyclohexene-1, 2-dicarboximide, which have low toxicity. Some systemic fungicides, such as metalaxyl, offer protection against fungal diseases up to maturity of the plant. Insecticides against bean stem maggot and thrips used for seed dressing include N-methylcarbamate, imidacloprid and thiamethoxam. “Do it yourself” seed treatment products containing both fungicides and insecticides are also available. Farmers producing their own bean seed may also take advantage of this technology by purchasing inexpensive packets of seed dressing pesticides. It is important that seed dressing products be colored in a way that they are identifiable and accompanied by warning messages so that treated seeds are not consumed.

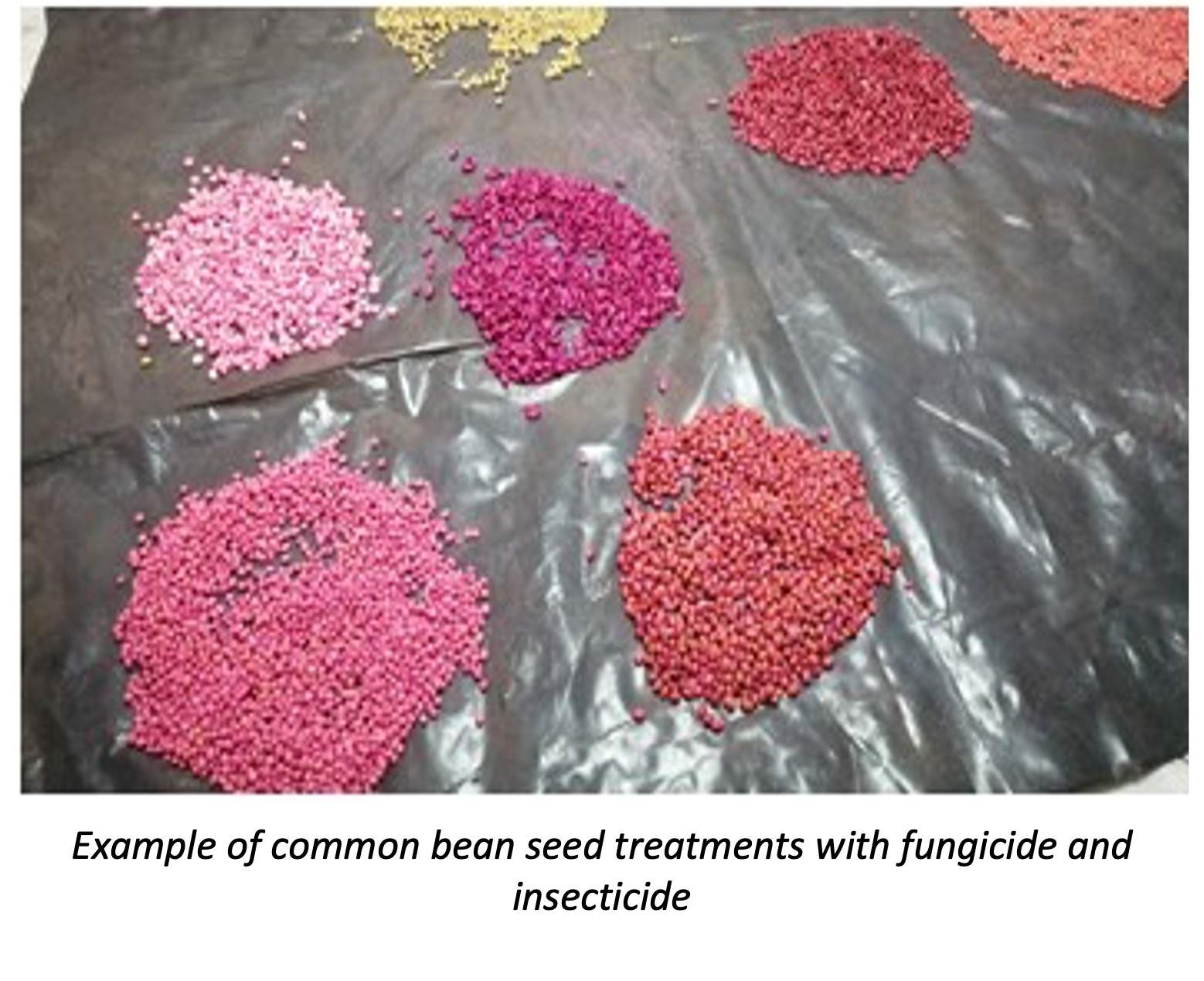

Bean seeds have to be weighed for ascertaining the dosage of chemicals that is required. Liquid formulas may be directly coated or after dilution, whereas dry formulas contain adhesives and are added directly to seeds. Seed dressings can be carried out manually using common receptacles or mechanically in mixers and hoppers. Treating smaller volumes of seed can be done inside a plastic bucket or basin, or by spraying seed with the solution on top of a polythene sheet. For dressing large volumes, community-based and commercial seed producers can make use of a rotary drum that is powered by hand or motor. Common beans that are treated with control agents are planted following recommended land preparation, spacing and fertilizer inputs in a particular growing area. Les agriculteurs qui produisent leurs propres semences de haricots peuvent également tirer parti de cette technologie en achetant des sachets bon marché de pesticides pour l'enrobage des semences. Il est important que les produits d'enrobage des semences soient colorés de manière à être identifiables et accompagnés de messages d'avertissement afin que les semences traitées ne soient pas consommées comme des aliments.

Commercialization

Commercially available

Solution Images

Institutions