Semi Autotrophic Hydroponics for Cassava Multiplication

Summary

In most areas of Sub-Saharan Africa cassava planting materials are produced through clonal multiplication, which involves cutting stems and planting these directly in the field. This process is however limiting the speed at which new improved varieties can be released to large number of farmers because it takes multiple years before sufficient volumes of planting materials can be produced. Obtaining good quality cassava planting material through traditional clonal multiplication is hard because the technique is prone to contamination with pests and diseases. Multiplying cassava through propagation methods that use seed and tissue culture is conversely limited by low multiplication ratios, i.e., producing few numbers a new planting materials from one seed. Semi autotrophic hydroponics (SAH) systems address these constraints on cassava multiplication, making it possible for farmers to have rapid access to new varieties. Benefits of the SAH technology over other techniques are its high multiplication ratio and the fact allows propagating true-to-type and pathogen-free cassava plantlets. Costs for producing cassava planting materials are also less when using SAH as compared to tissue culture.

About the Solution

Semi autotrophic hydroponic systems for crop multiplication were first developed for potatoes but have been adapted for cassava. The SAH technique is carried out in a laboratory and screen house, and involves placing modified soil, plant roots and little water in trays; which allows moisture to be transported while keeping the top of soil relatively dry. In SAH systems roots are encouraged to grow down, and the dry soil on top discourages damp-off and other diseases caused by excess moisture. Infrastructure requirements and costs of production for SAH are comparatively low, which makes that the technique can be easily implemented across dispersed farming communities in Africa. Because SAH plantlets have well-developed shoots and roots there much less need for replacement after planting in the field as in the case of cassava stem cuttings. The SAH technology allows to produce materials that are entirely free of pests and diseases unlike traditional cassava stem cuttings methods, which translated into higher resistance when planted in open field. Small-sized facilities for SAH propagation of cassava that have been set up in Africa are able to produce 7 million plantlets per year, simultaneously for multiple cassava varieties.

The SAH technology is suitable for rapid dispersal of improved cassava varieties in all major growing areas in Africa as it makes use of simple facilities and requires limited capital investments. Commercial biotechnology companies and community-based organizations can implement the SAH technique for propagating disease-free and high-quality cassava planting materials close to the fields where farmers cultivate the crop. This allows seed suppliers to bring early generation planting materials within reach for remote rural communities that rely on cassava for food and income. Planting materials that are produced using the SAH technique have a greater resistance to pathogens in open fields than those obtained from stem cuttings, and thus presents a viable strategy for combatting infestations and increasing yields in cropping systems across Africa. Also, with the production of disease-free SAH plants, transfers of planting materials between countries becomes much easier.

The required amenities for SAH multiplication of cassava include basic growth chambers or screen houses sealed off with nets with climate control systems, in which shelves are placed to hold trays with modified soils for plants to emerge. High-quality media are added to soils such as peat, rockwool, vermiculite and perlite that provide anchorage and plant support, hold up plant nutrients and water, and allow air gas exchange between the roots and the atmosphere.

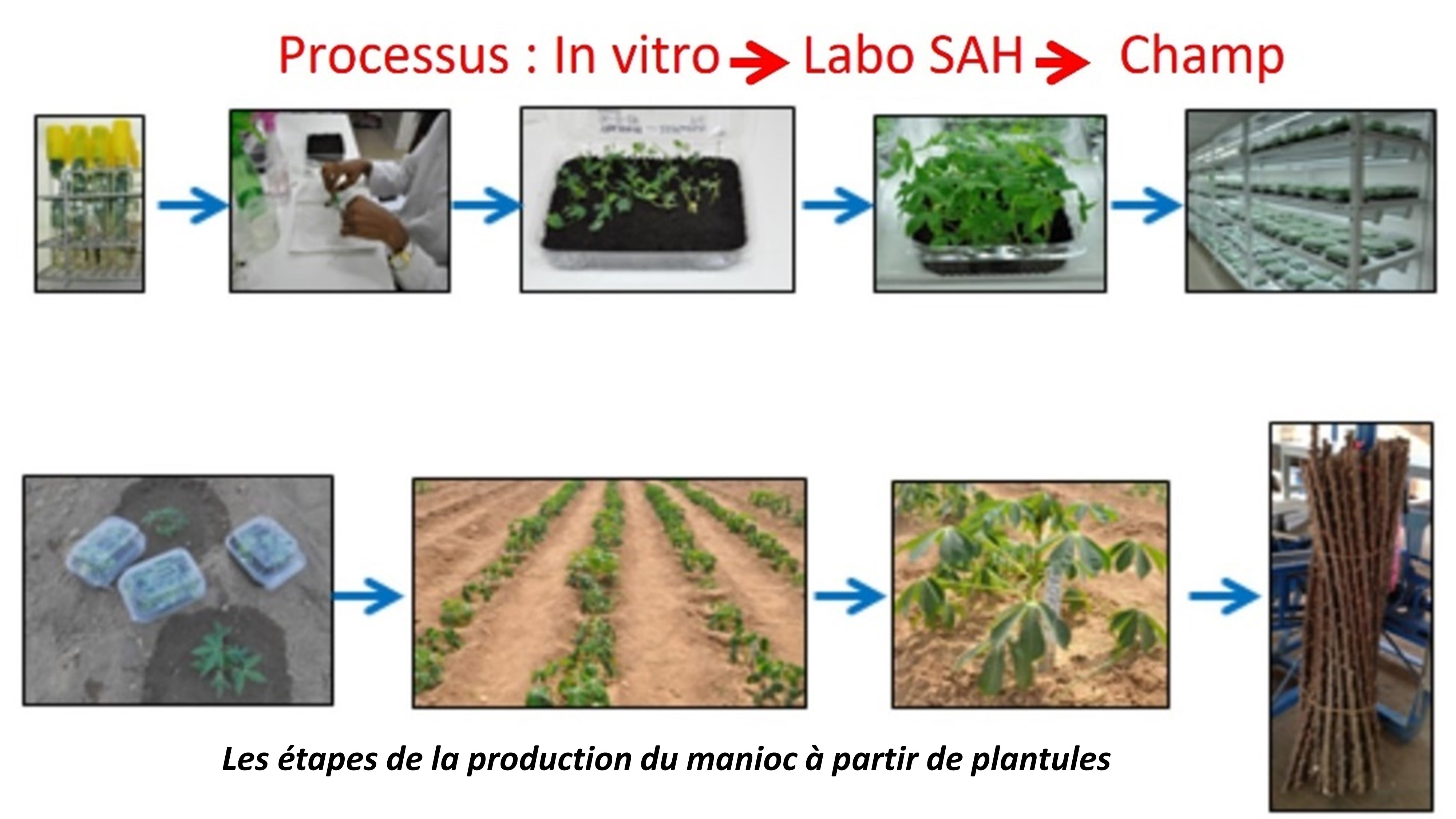

At the start of the SAH process, tissue cultured (in vitro) plantlets are produced under semi-hydroponic and semi-controlled environmental conditions, which are then cut into mother plants that are transferred into trays with growth media and placed in the growth chamber. After 2-3 weeks the mother plant are recut making two plantlets from one, which are then put back into the growth chamber for 6-8 weeks to develop rooted plants. Trays can transported in perforated cardboard boxes for over 48 hours, after which these can directly be planted in open fields for production or screen house for breeding.

Commercialization

Commercially available

Solution Images

Institutions

Accompanying Solutions

Disease resistant cassava varieties, Golden cassava varieties (Vitamin A fortified), Cassava varieties with high dry matter and starch content