Tank and Cage Systems for Fish Culturing

Summary

Tanks are enclosures placed on land to culture fish that are suitable for intensive production near urban centers with high market demand. Tank culture is a preferred alternative to ponds if limited amounts of water or land is available and the economics are favorable. Cage culture production involves growing of fish inside floating netted containers that are suspended within larger waterbodies. These cages require a comparatively low capital investment if locally produced. Cages also serve to clean waters through feeding activities.

About the Solution

Tanks should be constructed where there is year-round availability of quality water. Fish farming in tanks requires a complete feed diet with proteins, vitamins, and minerals as there is little to no natural foods available within the system. For cage culture, choosing the right location has a major influence on the economic viability of the operation. Inappropriate positioning of cages may cause poor fish growth, high mortality, and conflict with other water users. Feeding regimes for extensive cage culture rely upon natural foods and detritus, benthos, whereas more intensive culture also supplies fish feed.

Concrete tanks are best for rearing species such as catfish that can be farmed at high stocking density. Tilapia species can also grow well at high densities in tanks when excellent water quality is maintained. Extensive cage culture without additional feeding is better suited for microphagous tilapia species, such as Oreochromis niloticus, O. mossambicus and O. aureus; more than the macrophagous tilapia species, Coptodon zilli and C. rendalli. Flexible open cage systems are affected by the water flow that at higher velocities causes horizontal drag on the net and may reduce its volume. Suitable current speeds inside cages range from 0.1 m/s to 1 m/s for different aquaculture species.

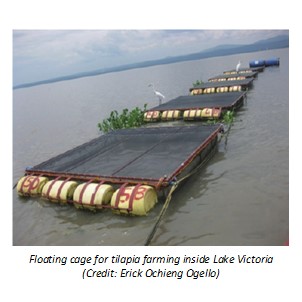

Fish farming tanks are made of concrete, wood, plastic, fiberglass, or steel in a variety of shapes, but the most common forms are circular and rectangular tanks. Different types of water and air supply systems can be used in tanks, including flow-through and recirculation. There are four basic types of cages: fixed cages, floating cages, submerged cages, and submersible cages. Cage frames are built with floatable pipes or barrels made from high density polyethylene, galvanized iron, or PVC plastic. Usually, a 1 to 2 inch (2.5-5 cm) nylon net is mounted on the cage frame to hold fish. Finer mesh sizes contain smaller fish but decrease flow inside the cage and increase horizontal drag because of water flow, which poses risk of damage under high current.

For catfish in tanks, 25-gram fingerling can be stocked at 1,500 fish per cubic meter to produce 50- to 60-gram harvests within 5 weeks, or at 1,000 fish per cubic meter to produce 100-gram fish in 9 to 10 weeks. To minimize mortality by cannibalism in tanks or cages, the stock must be sorted every two weeks, and faster maturing individuals removed. In tanks and cage systems it is important to remove uneaten feed or feces that accumulates underneath, avoiding proliferation of parasites and diseases. Adequate space below the cage (at least 3 m) ensures adequate water circulation through the cage and minimizes unwanted accumulation beneath.

Commercialization

Commercially available

Solution Images

Institutions