Flow-Through and Recirculatory Water Systems for Fish Tanks

Summary

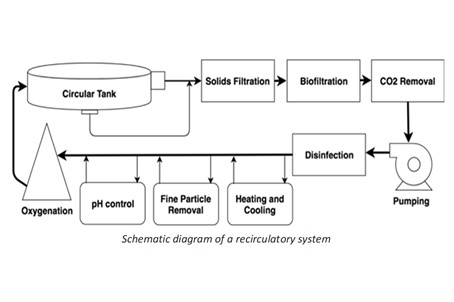

A recirculatory aquaculture system is a technology where water is recycled after filtration to remove suspended matter. This method is used for higher density culture of fish, allowing for maximum use of limited land and water. Water movement into and out of the tank maintains peak water quality conditions despite dense stocking rates. As water passes into the tank it provides oxygen and when it leaves it carries away waste products. Intensive aquaculture in tanks that operate at high stocking densities is furnished with a flow-through system that discharges water, cleans water, and pumps it back through the system. Tanks with a conventional flow-through systems are simpler in design but require an affordable and reliable source of quality water that can be used with minimal pre-treatment. Recirculatory systems are more complex and costly to install but have higher water use efficiency, higher feed conversion, and more exact disease control.

About the Solution

For successful fish farming in tanks, the water must have the required oxygen level and temperature for the cultured species. Tank volume and water flow determine the turnover rate, and the required time to replace the entire volume of a unit. Turnover rate is specific to the species being reared and their rearing density, but one turnover per hour is a good place to start for many species. Water passing through tanks simulates a current that can be adjusted by changing the position and direction of water flow. Fish should not struggle against this current, but rather be able to remain stationary with gentle movement. In a recirculatory system, water filtration is continuous, keeping the tank clean and providing a healthier environment for the fish. Waste products are either removed or converted into non-toxic products that can be used for cultivating crops. The purified water is then re-saturated with oxygen and returned to the fish tanks.

The most suitable location for a flow-through system is where there is reliable water availability from a river or lake, but limited access to electricity. In contrast, the best option for recirculating tanks is near cities with lower-cost and more reliable electricity but where temperatures are sufficiently high to avoid the need of heating.

Flow-through and recirculatory systems can be fitted to rectangular or circular tanks made of plastic, galvanized steel, or reinforced concrete. For both technologies, water pumps and flow meters are needed, with further sets of filtration and conditioning units for recirculating tanks. A settling pond is usually placed before water reaches the tanks to remove high loads of sediment and algae.

Setups of flow-through or recirculatory systems are determined by the water inflow and outflow rates, the tank shape and size, the water depth, the wall roughness, the inlet devices, and the presence of elements inside the tank. Circular tank designs have more stable flow patterns, a more homogeneous distribution of dissolved oxygen and metabolites and better self-cleaning features but are ultimately less space efficient than rectangular tanks. In a flow-through system valves are usually operated manually, and the visible turbidity of water direct the turnover in tanks. In recirculating systems, constant fish respiration can raise carbon dioxide levels high enough to interfere with oxygen levels and lower the pH of the water, thus requiring a buffering system. A series of components can be fitted before the tank inlet to regulate water temperature, oxygenation, and nutrient level.

Commercialization

Commercially available

Solution Images

Institutions