Hapa Nets for Mass Fingerling Hatchery Production

Summary

Inadequate supply of high-grade fingerlings from improved fish breeds is one of the main constraints to the expansion of the aquaculture industry across Sub-Saharan Africa. Poor and uneven growth rates, and high fingerling mortality present major limitations in open ponds. Birds, reptiles, amphibians, and even aquatic insects can cause massive losses in stocks of young fish. Artisanal and commercial hatcheries must achieve rapid and uniform production of fish stock for reliable supply to the local aquaculture industry, thereby allowing stable returns on investment. Small cage-like enclosures, referred to as “hapa” nets established within a pond are well suited to keeping brooders, hatchlings, and juveniles so they are readily accessible and protected from predators and other fish. This technology eases management of the brooder, fry, and fingerlings, as it enables operators to monitor the performance of their stock more closely and adjust breeding, feeding or aeration regimes. Hatcheries can realize higher fertilization rates of eggs, even growth of fish seed and reduced mortality, increasing production of fry and fingerlings per unit area with the right management of hapa enclosures.

About the Solution

Using hapa is a convenient means of collecting fry from the mouth of a tilapia brooder and rearing fingerlings inside a pond. The stocking density of the hapa affects fish survival, size variation and production rate, so it must be considered when determining the method and profitability of a hatchery. This simple containment system offers large benefits for all male fingerling production through manual sexing, hormonal reversal or YY male technology. However, management of brooders, fry and fingerling in the net enclosure is more demanding compared to traditional open-pond methods. Complete feeding regimes are required within the enclosure and must be adjusted during different stages of growth. Severe injury and mortality may occur due to aggressiveness among fish during spawning. Net materials degrade in sunlight and require periodic replacing. Storms, winds, or heavy rainfall can damage structures causing stock to escape. Hapa mesh becomes clogged over time and limits water circulation and aeration unless cleaned. Higher localized feeding can also lead to poor water quality within the net without adequate circulation.

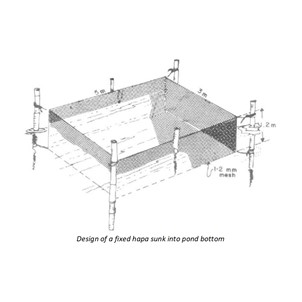

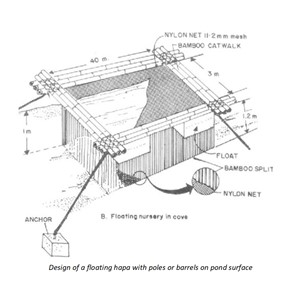

Hapa are simple to build with fine mesh screen netting material and wooden poles or floating barrels, making them affordable for any size of hatchery. Brooders, fry, and fingerlings from all common aquaculture species such as tilapia, catfish, carp, and prawn and crayfish can be stocked in hapa nets. The net enclosures may be installed in earthen ponds, riverbeds, and large concrete tanks, and the shape and size adjusted to the dimension and depth of a water body. In ponds that are fitted with a plastic liner (see Technology 4), there is need of floating types of hapa. Hapa can be set up in ponds that are stocked with other fish without risk of competition. They are suitable for shallow water (less than 1.6 m deep) with low water flow rate and level of fluctuation.

Various shapes and sizes of hapa are used, most commonly the enclosures measure about 3 m long, 3 m wide, and 1.5 m deep. Hapa are made of wooden poles that are sunk into the bed of the pond and a screen with mesh size of 0.01 mm to 2.5 mm depending on whether fry, fingerlings or fish are inside. Bamboo is ideal for constructing hapa since it is flexible in high wind. Polyethylene material is the most durable and cost-effective for nets. The net is attached to poles with nylon thread and double stitched to prevent splitting. A cover on top of the hapa prevents brood fish from jumping out and prevents birds from attacking the fish inside.

In fingerling production, use of hapa requires periodic scrubbing because the mesh will get clogged, therefore limiting water circulation. It could also result to poor water quality due to accumulation of uneaten feed and fish waste. They are easily cleaned by scrubbing with a brush whilst washing with pond water. Dirty hapa nets can be removed from the pond, soaked with urea for 72 hours, and washed with cleaner and rinsed. Fry production in hapa is normally done with brooders of 300 g average weight at a male to female ratio of 1:2 or 1:3, and stocking density of 4-5 brooders per square meter. Hapa should be inspected for fry every day, which are subsequently transferred into other hapa tanks or rearing ponds. The hatchery operator must record the number of fry and fingerlings that are harvested from individual hapa along with feed input to monitor and achieve high levels of rearing efficiency.

Commercialization

Commercially available

Solution Images

Institutions