Motorized weeders for rice production (cut and bury)

Summary

Keeping encroachment of rice crops by weeds under control is a major problem for millions of smallholder farmers in Sub-Saharan Africa (SSA) that clear paddy fields by hand, owing to the high labour-demand and large cost of this traditional practice. Poor management of weed is estimated to be responsible for grain yield losses of at least 2.2 million tons per year across the whole of SSA, respectively worth US $ 1.45 billion and almost half the total imports of rice. Small-sized motorized units for weeding in between the lines of rice crops exist that greatly speed up the work and cut down on labour requirements in comparison to manual clearing of paddies. The low capital costs and high efficacy of these mechanized technologies bode well with smallholder rice farmers, and has fostered their successful widespread scaling in rural communities of Asia and South-America over the past decade. Improvements of weed control in paddy fields achieved with simple motorized equipment are directly increasing rice grain production and quality, and reducing needs of fertilizer input and additional irrigation.

About the Solution

Walking tractors designed to uproot, cut and bury weeds within the lines of evenly planted rice crops that make it possible for one person to clear one hectare of paddy field in ten hours whereas it would take more than 100 hours with manual labour. The specific design of the weeders ensures minimal disturbance to roots of rice crops and soil surfaces of farms. Litter from cleared encroacher plants decomposes underground where it delivers nutrients back to crop stands. Units are propelled by small engines that limit their weight and allows for easy passing and turning over fully soaked paddy soils, with weeders of one horsepower typically clearing three rows at a time. Blades on top of the wheels give forward traction to the machine while weeds are thrashed, and their width has to be aligned with the spacing between rows. Farmers can utilize motorized weeder technologies to clear paddy fields as soon as rice plants have sprouted and up until the canopy closes at flowering stage (week 8). Hands-on demonstrations of rotary power units with rice growers in Tanzania and Madagascar found that 85% consider it to be a cost-effective and time-saving option for clearing weeds from paddy fields. Walking tractors with rotary blades typically clear 70-80% of weeds from rice fields in one go, but nonetheless produce similar grains yields as when more than 90% of weeds are picked by hand.

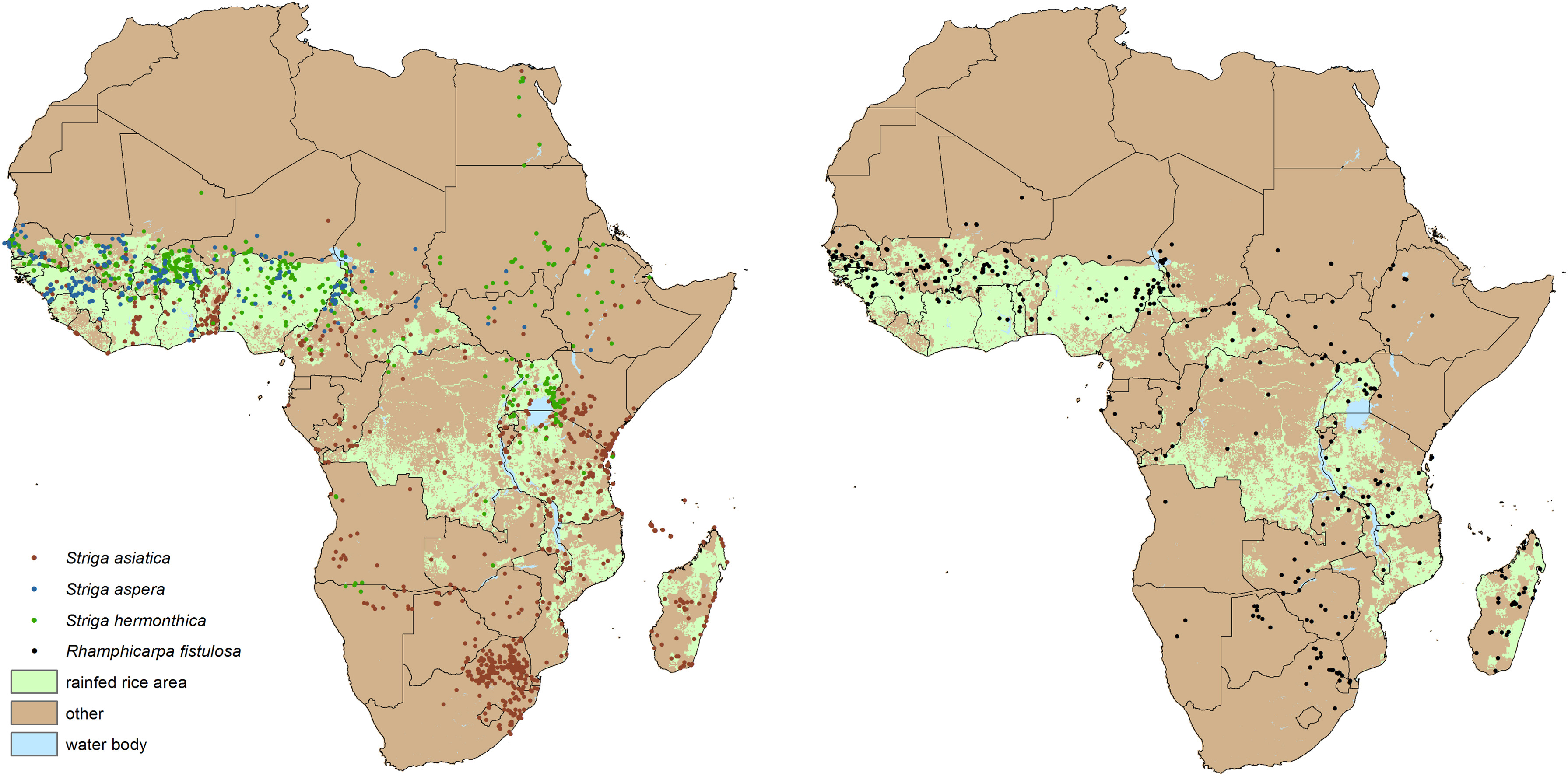

Unsatisfactory weed control is one of the main limiting factor for rice production across SSA due to widespread dependence on manual removal and low levels of herbicide application that are unable to control high rates of infestation and distribution. Motorized weeding units are technically and financially suitable for both subsistence and commercial farmers, which offers unique opportunities to improve on current levels of crop protection and grain production under diverse agro-ecological and socio-economic contexts. Specific types of rotary power weeders are designed for operating on waterlogged or dry soils that allow using the technology in flooded lowlands and rainfed uplands. All of the weed species occurring in rice fields across SSA can be effectively managed with motorized units, including parasites like Striga and Rhamphicarpa.

Walking tractor units for weeding in between lines of rice have one or more wheels fitted with J-shaped blades pointing against the direction of travel that enter the soil up to a depth of 10cm depth, and thrash shoots and roots by pulling them under. The width of blades is determining forward speeds, depth of operation, plant damage and weeding efficiency; which needs to be altered in line with the characteristics of soil and farmer objectives. Units are propelled by compact two-stroke petrol motors with one to five horsepower and maneuvered with the handle bar mounted behind the wheel axil. Multiple agricultural equipment manufacturers are selling completely assembled rotary power weeders, and crafters in rural communities can also construct units with locally available parts.

Rice crops have to be planted in even lines at a spacing of more than 15cm for motorized weeders to be maneuvered easily over paddy fields and to avoid damaging the root system underground. Depending on the level of weed encroachment and rate of canopy growth farmers are required to use the rotary power units one or two times on rice paddies for achieving a satisfactory level of control. The walking tractors can be passed over and turned on water logged fields by one person, but to cover larger areas two or more workers are required. Common herbicide and pesticide agents as well as biological control measure can be applied in rice cropping systems alongside with motorized weeding units to form integrated crop protection strategies that push up yield potentials. While some farmers have the means and interest to buy a motorized weeder on their own, there is need for collective purchase and shared use, or private agricultural service contractors, for scaling the technology across low-income rice growing communities of SSA.

Commercialization

Commercially available

Solution Images

Institutions

Accompanying Solutions

Selective herbicides (pre-emergence and post-emergence)