Seed Inoculation with Rhizobia

Summary

The productivity of legumes is often limited by the availability of soil nitrogen (N), a condition that may be addressed not only through application of mineral fertilizers and organic resources but also of symbiotic Biological Nitrogen Fixation (BNF). This process occurs in root nodules where rhizobium bacteria transform plant sugars and nitrogen gas into amino acids. Inoculating planted seed with elite strains of rhizobium (such as CIAT 899) that have been selected for high plant compatibility and N fixation ability increase the transfer of N. These bio-fertilizers are available as dry or liquid formulas for seed inoculation from private companies, national agricultural systems and research laboratories. Seed inoculation with elite rhizobium has demonstrated to be a cost-effective technology for increasing legume production on small-scale farms in Africa that depend on it for food, nutrition and income.

About the Solution

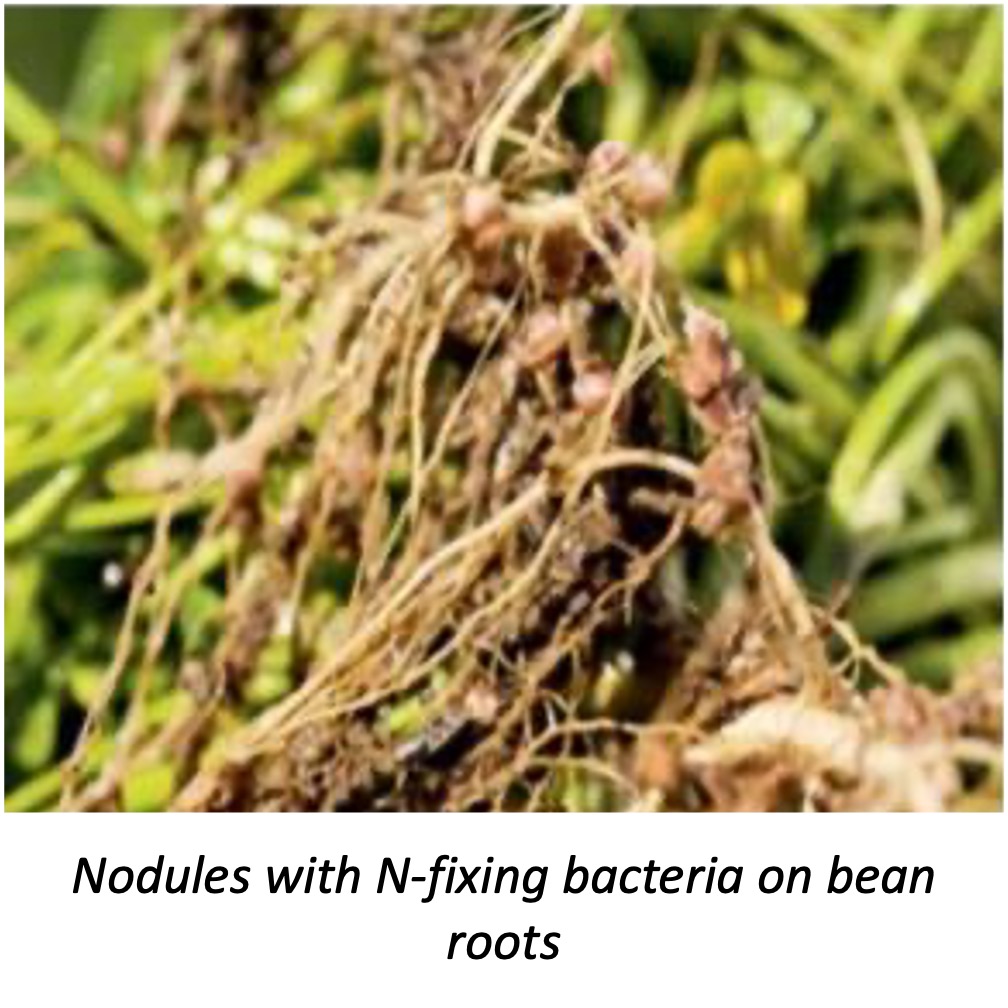

Seed inoculation involves coating elite rhizobial bacteria onto seed just before planting, a practice that warrants effective symbiosis and high levels of nitrogen fixation. As legumes germinate, the beneficial microorganisms colonize the roots by developing nodules where the host bean plant supplies carbohydrates in exchange for readily-available N fixed by the rhizobium that the crop uses for assimilating proteins and other compounds. Nodules are visible on root surfaces and when actively fixing N their interior is pink or red. Rhizobium bacteria are specific as to which type of legumes and crop variety they effectively associate with and this forms the basis of matching strains with hosts like common bean. Because many agricultural soils in Africa lack highly effective native rhizobial in their soils, it is recommended that farmers introduce elite rhizobia. The manufacturing of high quality inoculants enables widespread deployment of this technology in production across African countries. Improvements to formulations and the advent of inoculants’ quality control systems have played an important role in this commercialization.

Seed inoculation with elite rhizobia is a financially and environmentally sustainable approach to increase N availability for common beans. The low cost of the BNF technology compared to inorganic fertilizers makes it attractive to both small-scale farmers with limited resources and commercial farmers who seek to reduce costs of production. N fixation is sensitive to soil pH (the optimal being 5-8), low phosphorus availability, extreme temperatures, drought and excessive moisture. There is large scope for inoculation of legumes on soils that suffer from nutrient depletion but requires accompanying inputs of phosphorus, micronutrients and lime to effectively harness its benefits for enhancing production. The technology however needs to be carefully implemented since the presence of large numbers of less effective native rhizobia in soils may reduce the benefits of inoculation, confusing those who adopt it.

Inoculant products for common beans typically contain single or mixed strains of rhizobium such as USDA 9030 or CIAT 899, strains with widely proven abilities for nitrogen fixation. The exact strain that is used for inoculation may vary between particular regions since it needs to out-compete native populations with lower N fixing ability. Solid formulation inoculant products also contain a carrier material that protects rhizobia during storage and transport, and allows for ease in handling and application. These inoculants are mixed with adhesives such as gum Arabic solution to coat the inoculant onto seeds just before planting. There are also liquid formulas that can be applied to seed that are better suited for mechanized planting.

Banks of elite rhizobia strains are conserved by dedicated laboratories and transferred to commercial manufacturers who produce inoculant products by culturing them under controlled conditions. Proper storage and handling of these inoculants is key to protecting their efficacy for seed treatment. This includes protection from direct sunlight and overheating. Dry inoculants may be applied using either the two-step or slurry methods, with the latter approach preferred for larger quantities of seed. Liquid formulas are sprayed onto seed or applied within mechanical seed hoppers. Inoculated bean seed is planted in a manner that restricts direct exposure to sunlight and it is best to inoculate and plant the seed during the same day.

Commercialization

Commercially available

Solution Images

Institutions