Flour Milling and Blending Systems

Summary

The time and energy required for grinding and cooking the grains of millet and sorghum for consumption poses a burden in home kitchens and restricts its appeal in urban centers. Farmers and traders can quickly add value to millet and sorghum by milling their grains into flour that is easy to use and ready for blending with other flours. Millet and sorghum flour are gluten-free and suitable for a variety of food products such as bread, biscuits, cakes, porridges, and even pasta. Techniques for flour milling however must meet industry quality standards and consumer preferences. Different small- to large-scale milling and blending systems are available that allow production of premium flour products in both rural and urban areas. The advantages of local flour processing are the reduction in transport and costs to rural consumers and value addition to raw grain of products sold to urban markets and food processors. Building capacity of rural communities for millet and sorghum milling and its blending into multi-purpose flour can massively boost output, value addition and competitiveness of local processors.

About the Solution

Millet and sorghum as food crops have a high protein content and well-balanced amino acid ratios. Their long cooking times that can be considerably reduced through processing. In this way, practical and economic advantage is derived through milling millet and sorghum into flour. Producing flour may be considered a business art that begins with selecting the right factory location, followed by procuring the right variety at the right price, followed by cleaning, milling, and blending. Locations for processing should be close to major growing areas that can provide a reliable supply of quality grains and have convenient transportation routes for easy delivery of raw and shipping of final products. In selecting the millet and sorghum varieties for milling and blending, it is important to take the hardness into consideration because it strongly affects annealing strategies of heat treatment to relax starch structures. Blending procedures must also be conducted in accordance with sedimentation and index values that determine flour quality which are closely watched by food manufacturers. Another purpose of annealing ensures the optimum moisture level for milling and to enhance flours wetting ability.

Sorghum flour is a gluten-free flour with a mild, sweet flavor and smooth texture. It's commonly used to make gluten-free cakes, breads, and other baked goods, either on its own or in combination with other gluten-free flours such as rice and cassava. It can be used as a 1:1 all-purpose flour substitute in just about any recipe. Sorghum and wheat flour blends are well suited to baked products, including yeast-leavened bread, flatbreads, cakes, muffins, cookies, biscuits, and flour tortillas. Millet flour has a subtle, slightly sweet flavor. It is used in the same way as sorghum flour and as a 1:1 substitute for wheat flour, particularly in pancakes, flatbreads, muffins and cakes. It works well in recipes such as pizza crust and fritters, and makes a good thickener for stews. In comparison to conventional preparation by lengthy boiling, use of flour offers substantial savings on cooking time and fuel cost, and improves the bioavailability of vitamins and micronutrient in derived food products. Flour milling and blending technologies for millet and sorghum improve African food self-sufficiency and promote business development in rural communities.

Pearl millet's average composition is 70% carbohydrates, 16% protein, 5% percent fat and 3% ash. It is higher in phosphorus, iron, and calcium than maize or wheat. Sorghum typically contains 63% carbohydrate, 11% protein, 3% fat and 2% ash, with varieties containing lower amounts of tannin most suitable to flour production. Both grains are gluten-free and have numerous documented health benefits including boosted immunity and reduced blood cholesterol.

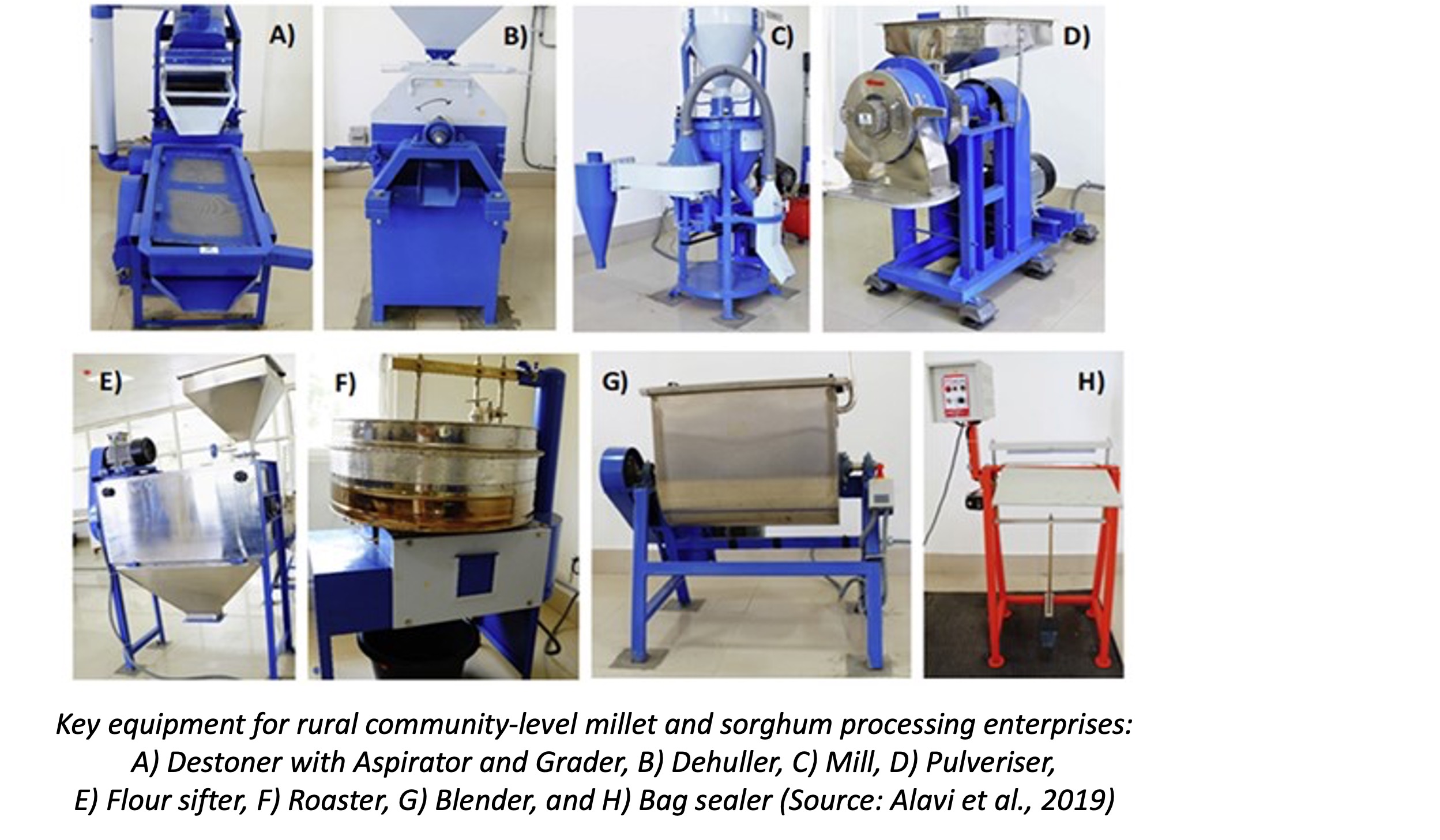

Before establishing a flour milling enterprise, one must be sure about location, supply, and market so investments are not made at the wrong location. Based upon this information, suitable finance mechanisms can be identified for approaching investors. When funding is secured, then equipment for cleaning, annealing, and milling must be purchased and assembled into a flour processing line. Reliable supply of electricity is very important and backup systems should be in place. There is need for continuous quality assurance of the flour to ensure product compliance with market standards on sedimentation and index values. There is a wide range of equipment for processing millet and sorghum grain. A typical air-screen cleaner consists of four screens that are located beneath a hopper. Grader machines that sort out impurities based on width and thickness are comprised of cylindrical screens that are horizontally positioned and have round perforations. Separators that select grains by length, density or gravity use angular sieves and forced air, which can be adjusted according to specific needs. An abrasive grain mill has a feed-in hopper, roller table for grinding, rotary sieve for bran separation, and a conveyor belt.

Commercialization

Commercially available

Solution Images

Institutions