Low-Cost Cage and Free-Range Containment

Summary

Housing poultry protects birds from predators and climate extremes in ways that minimize stress and enhance productive gain. In addition, suitable housing contributes to ease of collecting wastes, biosecurity, sanitation, and feed management. Commercial poultry production requires sophisticated housing types and automated equipment. However, most smallholder farmers cannot afford the cost of building elaborate poultry houses. In addition, consumer interest is growing with regard to organically produced foods and free-range birds receiving access to green vegetation and outdoor, rather than caged conditions. As a result, there is rapid growth in demand for construction and deployment of movable pens. This mobility also prevents the accumulation of pests and disease, reduces feed costs, and naturally spreads manure across fields.

About the Solution

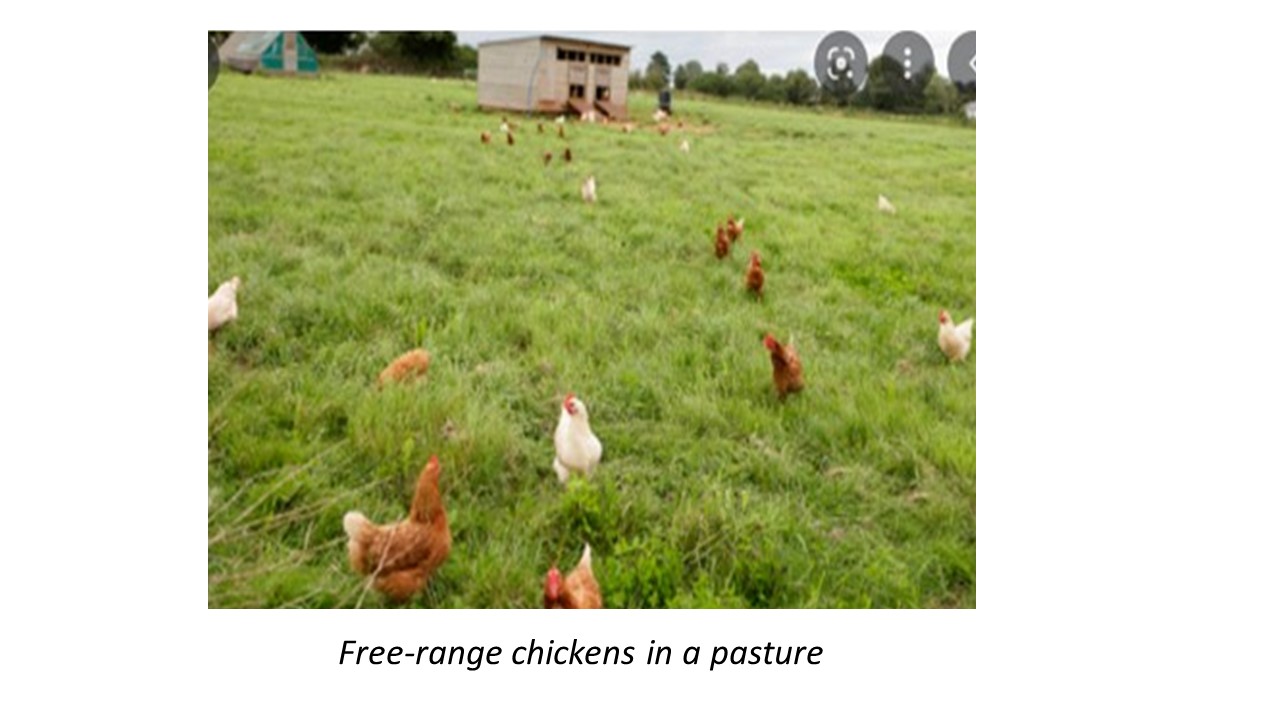

Moveable, low-cost poultry sheds accommodate free-range chickens. These houses provide night shelter and are usually equipped with nests and perches. During the day, birds are permitted access to surrounding fields where they scavenge and feed. The birds are not confined to battery cages or crowed pens like in conventional industrial scale production systems. Improved dual purpose chicken breeds such as Kuroiler and Sasso are best raised in low-cost, free-range conditions. Besides shelter, the chickens receive supplementary feeds in form of formulated ration, water, and necessary vaccinations against virus diseases. In contrast to intensively reared chickens, free-run chickens are usually not administered antibiotics. Access to green leaves, insects and worms assures a strong immune system and healthy chickens. Organic chicken production is more feasible under free-range conditions.

Low-cost, movable containment and free-run poultry operations chickens is practiced at a commercial scale in many countries, including Kenya, Nigeria, Cote D’Ivoire, Ethiopia and Ghana. This production is well suited to peri-urban areas and integrated into cropping by moving chickens around within blocks of open land.

The materials required for constructing a movable, free-run chicken pen includes wood, roofing sheets and flexible galvanized chicken mesh of 0.3 cm to 1.0 cm dimensions. Chickens require about 0.2 m2 of floor each or 20 m2 for 100 birds. For layers, an additional 0.03 m2 nest box is required, positioned in ways that allows easy access to eggs. In general, houses should not be longer than 5m to 8m or they become too difficult to move. Larger houses can be equipped with wheels or rollers for ease of moving it around.

Poultry houses should have good ventilation by providing about 30 cm of mesh on top of two opposite sides. Ventilation provides fresh air and regulates house temperature. It facilitates expelling of CO2, ammonia, moisture, dust, and odor. It should have a disinfectant dipping vat at the entrance. The house should be cleaned and disinfected between production batches and after removal of accumulated manure. Other basic requirements for these poultry houses include good drainage, placement on level surfaces and secured entry against predators, wild birds, and rodents. The house should be aligned in an east-west orientation to minimize prolonged sunshine inside the house. The floor of the house can be raised about 0.2 m from the ground and finished with mesh to permit dropping to fall through to the ground.

Commercialization

Commercially available

Solution Images

Institutions