Pond Liners to Save Water and Ease Maintenance

Summary

Sheets of ultra-violet resistant polyvinylchloride, polyethylene or similar materials form an impermeable layer between the water and the soil which decreases water losses through seepage. It also reduces evaporation, improves temperature regulation, helps prevent algal blooms, and promotes nutrient cycling between water and sediment. Many soils require liners to hold water, particularly sands and silts. The technology is easy to install and maintain and is environmentally friendly. Liners are resistant to puncture, UV light, oxidation, and chemical reactions. Quality lining material that is properly installed has a low chance of leakage or breakage, making the technology an affordable solution for small-scale and commercial fish farming.

About the Solution

Pond lining is an adaptation strategy to preserve water, reduce the spread of pathogens, and realize higher biosecurity. Synthetic “geomembranes” keeps water cleaner and make ponds easier to maintain. Rubber or plastic liner material is affordable for smaller sized fishponds. They may last for more than ten years. Plastic liners for sealing tend to be stiff and more difficult to install in small ponds but they are stronger than rubber liners. Water in fishponds also serve as reservoirs for irrigation as a cushion against drought. Pond liners are most important in areas with sandy soils or locations away from water bodies.

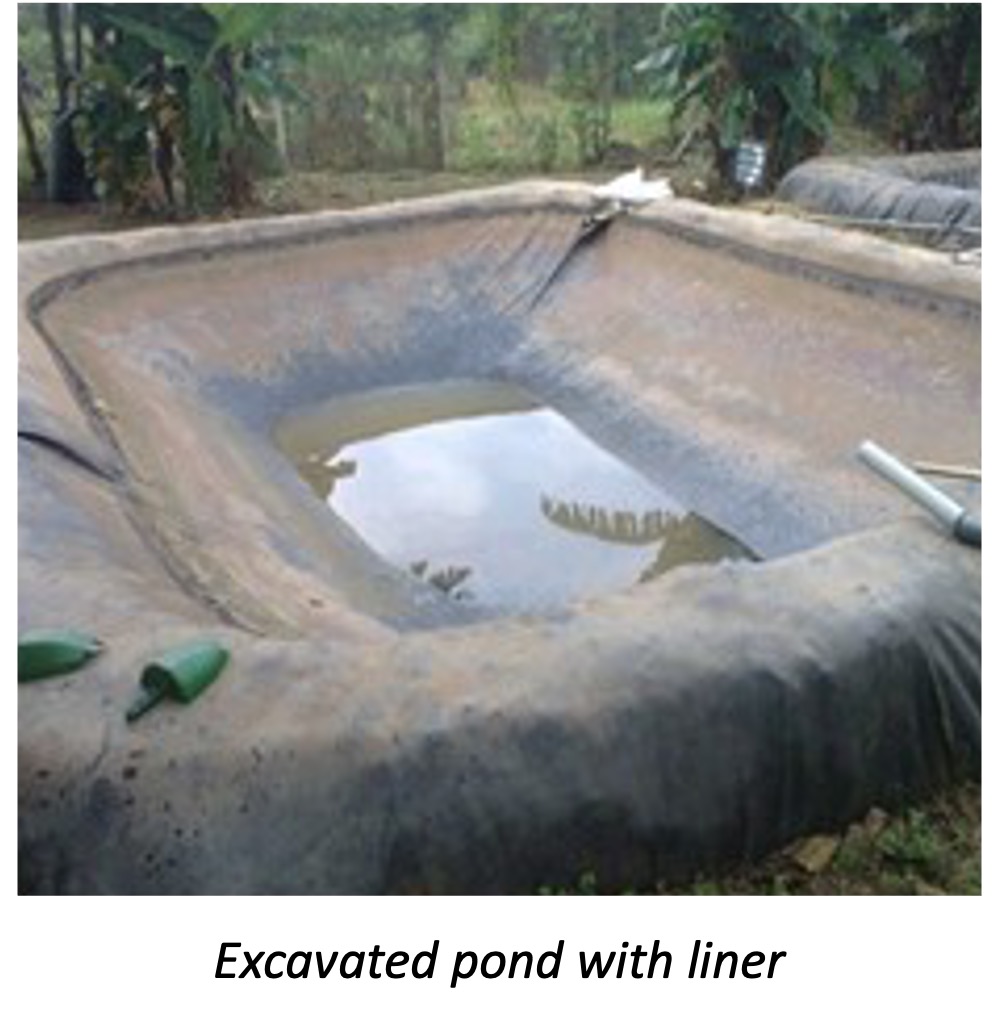

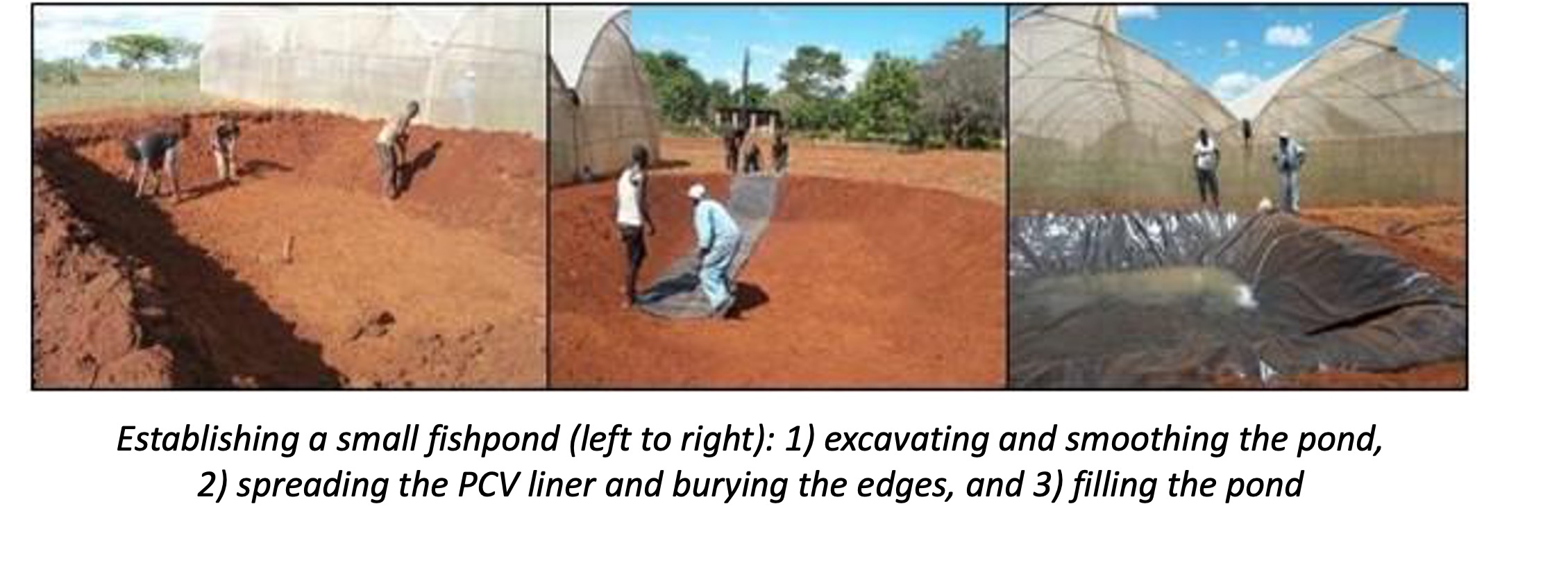

Liners are installed into ponds constructed on flat or gently sloping land. This water conservation technology is most suitable for areas with porous soil and/or poor access to running freshwater. Liners can be fitted into any size or shape of pond. Rubber sheets are more flexible and conform to the contours of pond features quite easily but are not as strong as plastics.

Pond liner is available in different types of material including polyvinylchloride (PVC), reinforced polyethylene (RPE), ethylene propylene diene monomer (EPDM) or high-density polyethylene (HDPE). These come in different thickness ranging from 0.5 mm to 3.0 mm which are suitable for different sized ponds and surface roughness. Liners must be stable to exposure from UV light. RPE is usually recommended as it is stronger, lighter, and less expensive than EPDM and HDPE, but stiffer to work with. The PVC is least expensive but less puncture resistant. Under layers of woven polyester or polypropylene may be included as well to offer greater protection from sharp rocks, probing roots and burrowing rodents. High-density polyethylene liners are the most widely available. They are heavy duty, puncture resistant, can be connected into large sheets by “hot wedge welding”, flexible and UV stable. They have fish-safe properties and readily conform to pond surfaces. Their density is about 0.94 g/cm3 and they are nearly pure, with small amounts of carbon black added for UV protection and antioxidants added to increase durability. They are available in thicknesses from 0.5 to 1 mm, with thinner widths suitable for smaller ponds without stones.

The amount of liner required depends upon the dimensions of the pond, its intended volume, and the slope of its walls. One can use a simplified formula: Volume = (d/6) x (At + Ab + 4 Am), where V is volume, d is depth, At is the area on top, Ab is the area at the bottom, and Am is the area at half the depth. An extra 50 cm must be added where sheets are overlapped to ensure watertight seals. For seaming two sheets, clean a strip of 25 cm along both edges with rubbing alcohol so the adhesives bond well, then apply primer in a 15 cm strip along the top of one piece of liner and lastly glue the two sheets with double-sided tape. Polyethylene may be heat sealed as well. Remove shoes when stepping on the liner to prevent it from getting pierced. When filling the pond with water, pull and tuck the liner into shape to ensure a neat finish.

Commercialization

Commercially available

Solution Images

Institutions