Value Addition and Storage Techniques

Summary

Currently, less than 30% of chicken meat is processed into clean precut preserved products across African countries. Most poultry are sold on live markets and slaughtered on-site which gives farmers lower returns and causes supply shortages and public health hazards. Secondary processing of whole raw chicken into value-added products and cold storage allow sales to a larger consumer base all year round thereby increasing revenue for producers. The demand for ready-to-cook or precooked chicken meat by households, institutions, and restaurants is rapidly increasing due to urbanization, income growth, and awareness for healthy diets and food quality. Expansion of product ranges and sales of processed chicken meat is limited by a lack of adequate technology and skill, insufficient cold chain facilities, poorly organized marketing system, and trade barriers. Mechanized equipment makes it possible to process high volumes, and refrigerators and freezers allow long-term storage and long-distance transport. Value addition and storage facilities are available for small and medium enterprises, and farmers can form cooperatives to raise sufficient capital and volumes.

About the Solution

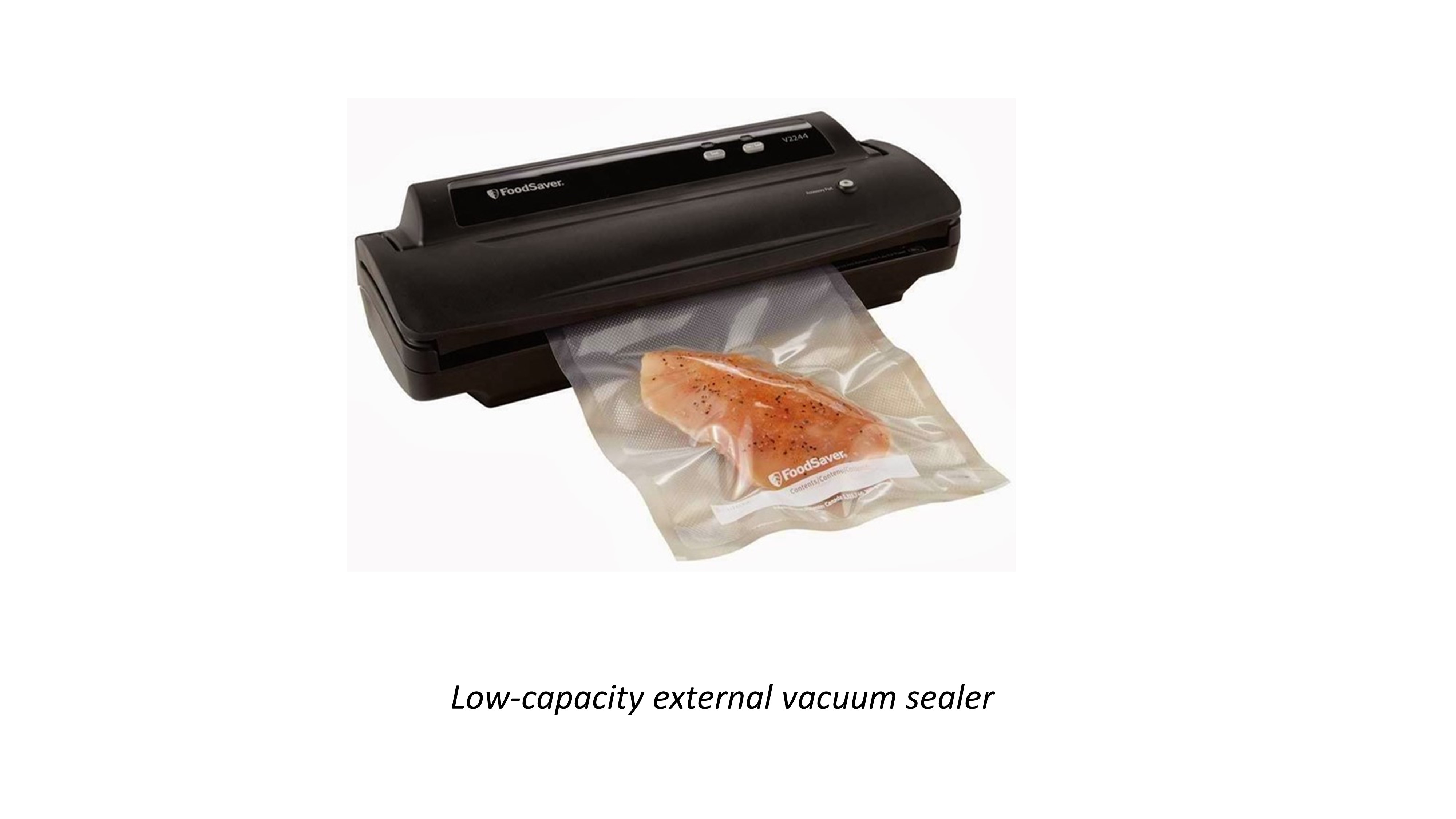

Poultry farming is showing rapid growth across Sub-Saharan Africa, but the secondary processing industry of this value chain does not advance at an equal pace. Precut and precooked chicken are convenient for consumers because they reduce preparation time, offer relished portions and parts, reduce health hazards and risks of home butchering. Processing and storage technologies make it possible to expand the range of poultry products, augment value for producers, stabilize supply on local markets, and upgrade this agro-food industry. Strict hygiene and quality norms of processed poultry products must be maintained to promote marketing and consumption patterns. Small electric slicers, deboning machines and grinders are best suited for low volume poultry processing, while fully automated outfits exist for large enterprises. Packaging for storage, transport and marketing can be done using wrapped trays or airtight packages, each serving different markets. Chamber-style vacuum sealers allow strict portion control, long shelf-life, and high food hygiene. For preservation, processed poultry products must be rapidly cooled to 4°C within two hours after slaughter, achieved through different combinations of forced air, water immersion, spray, or vacuum chilling.

Semi-automated processing plants for small to medium-scale operations are usually located on poultry farms that have a capacity of handling a few thousand chicken per day. Fully mechanized chicken processing plants are located close to clusters of large poultry farms and usually have a capacity of more than 50,000 chickens per day.

Equipment for cutting, deboning, grinding, and chilling can be bought as individual components or as an assembly production line. Depending on preferences of consumers poultry can be processed into two halves or separated into wings, legs, and breasts, with or without skin and bones. Further processing involves ready-to-cook marinated, chopped, breaded, crumbed, glazed, roasted, fried, and grilled products.

After defeathering and disembowelment the whole bird is passed onto cutting stations where it is divided into different parts. Deboning is most common for breasts (fillets and tenders), and sometimes applied to thighs. Before packaging and chilling, the clean and cut meat is portioned based on weight, length, width, and thickness. This step is key for marketing, price control and food safety. Restaurants and fast-food kitchens rely on portioning since they apply standard cooking procedures where meat is placed in a fryer at a set temperature and time. Portions that are too heavy or thick will not reach a safe internal temperature with programmed settings.

Commercialization

Commercially available

Solution Images

Institutions